The main purpose of the garage is to store cars. However, this does not prevent car owners from using it for other purposes: storage of preservation, tools, household appliances, unnecessary things, car spare parts. Over time, mountains of various household items accumulate in the room. The garage is slowly turning into a chaotic landfill, with less and less space. This is a sign - it’s time to correctly organize the space by installing shelves in the garage. They will allow you to rationally put things, save useful space, improve the interior of the room.

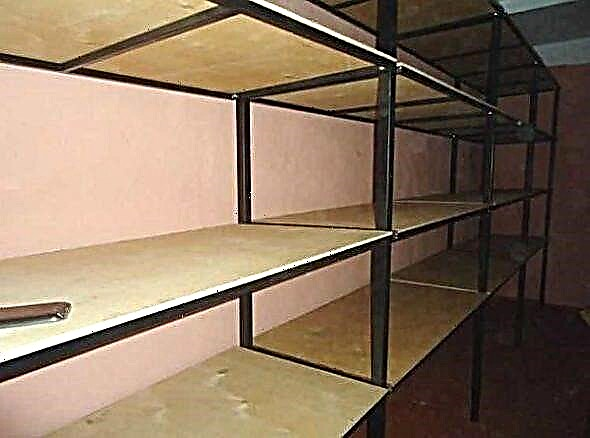

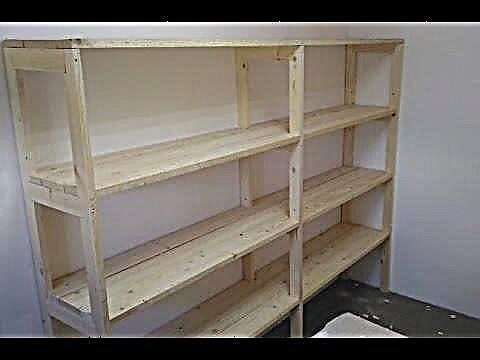

Garage with a convenient storage system when everything is in place

Do-it-yourself shelving in the garage is quite simple. You need to prepare tools, buy some materials, free several hours from work. In this article we will consider detailed instructions, some tips, recommendations for arranging such a design.

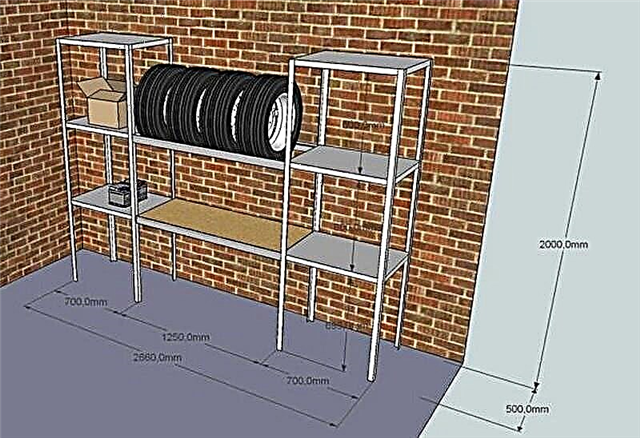

Shelving with storage shelves

Welded, bolted rack: which is better?

Permissible loads on makeshift shelves in a garage

Before planning shelves for a garage, you need to determine a more convenient way of fixing them. Two methods are most popular today: welded, bolted. Welded technology is usually used for metal structures, bolted - wooden. Both technologies are working properly. Such shelves in the garage are convenient during operation, withstand heavy loads. However, they have some disadvantages.

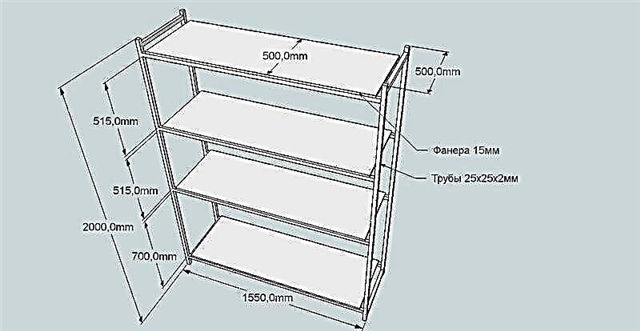

One of the options for shelving with a frame from a profile pipe and shelves made of plywood

Welded shelves are non-separable. When you change the plan of the garage, its purpose, just disassemble the product will not work. Transporting welded shelves is also inconvenient. Their weight can exceed a hundred kilograms. The main advantage of this design is its reliability. Welds firmly fix the elements together. To achieve their destruction is not easy.

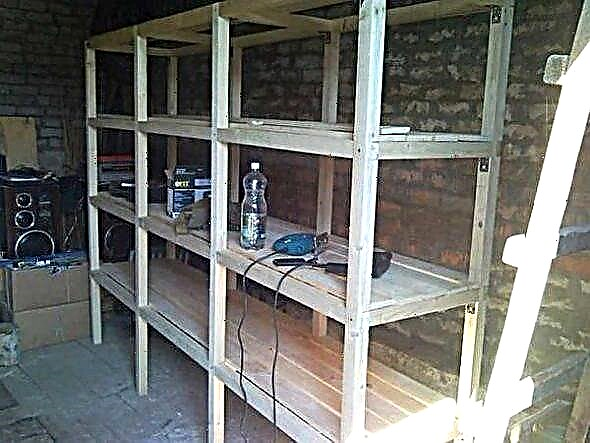

It’s better to connect a wooden garage rack to nails rather than self-tapping screws, so they become less loose

Bolt racks are less stable. They cannot provide sufficient rigidity. For stability, the structure has to be additionally fixed to the wall. However, there is a significant plus to this method of attachment - mobility. Shelves can be disassembled, assembled, mounted shelves of various sizes. It is impossible to give a definite answer to the question which of the technologies is better. Each person will have their own important parameters.

Determine the design

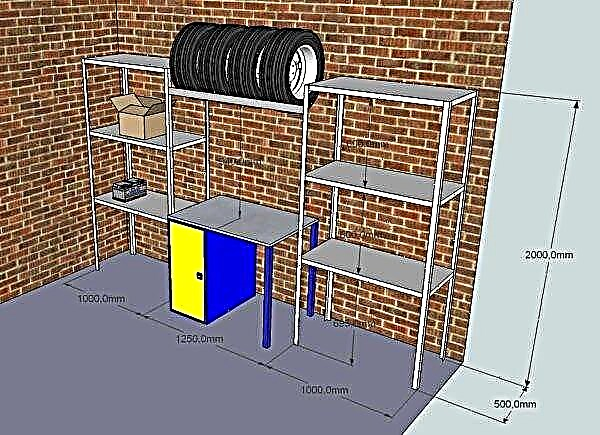

Scheme of the simplest rack in the garage

Making racks in a garage with your own hands is quite simple. The most important thing is to clearly define your own desires, needs, pre-plan the design, type of construction. Such tasks will be within the power of anyone, especially if there is a great desire to do something with their own hands.

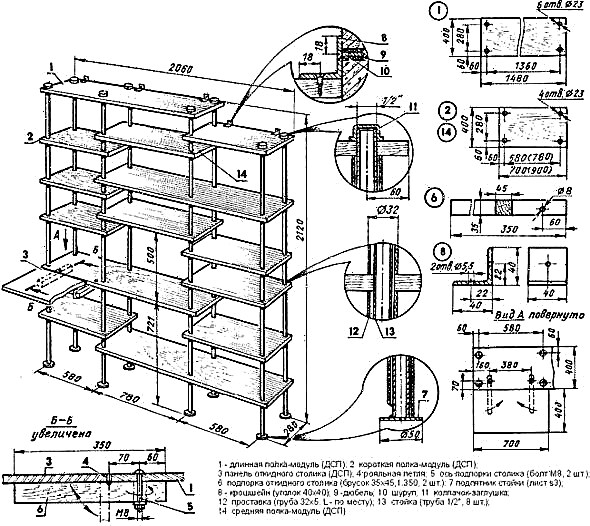

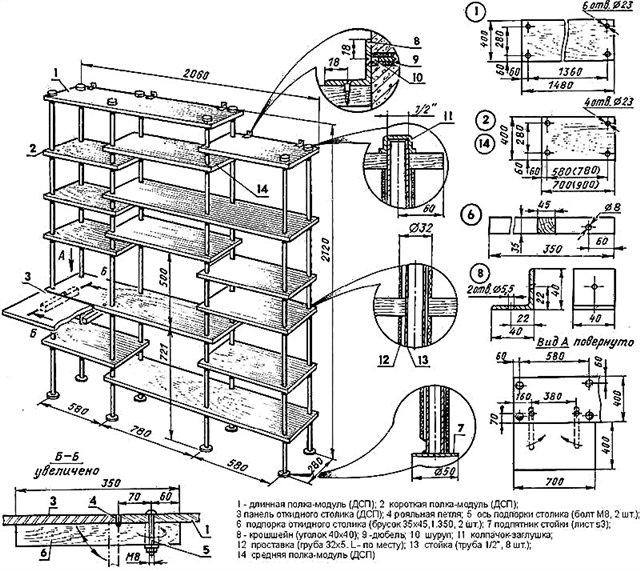

Drawing of a pipe rack with wooden shelves

The design of the racks has three elements: vertical racks, shelves, crossbars. In some cases, lateral tightening is used. They are not required. Only needed to increase the rigidity of the frame. To determine the exact design of the future rack, follow these recommendations.

- Depth, height of shelves - arbitrary. These parameters are selected only based on the purpose of the niche. Each shelf can be designed to store a certain type of thing. All this is best decided in advance,

- The distance between the uprights must be selected based on the stiffness of the material. For very heavy accessories, the distance should be about 1.5 meters. For a long shelf, intermediate vertical racks must be prepared. They will make the system more stable,

- The lower shelves should be at some distance from the floor. Approximately 50-70 cm. Heavy objects should be stored on them. The optimal height of the remaining shelves will be 37 cm. This is the most rational height, often used in the manufacture of any furniture design.

Drawing of a metal rack for a garage

Deciding on design features is always easy. The owners of the garage just take into account the dimensions, especially the things that will be stored in the structure.

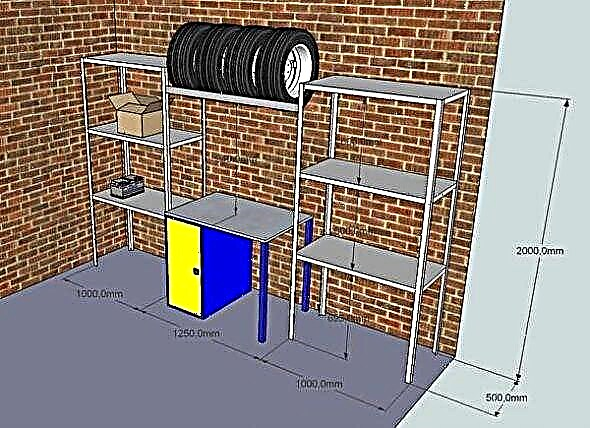

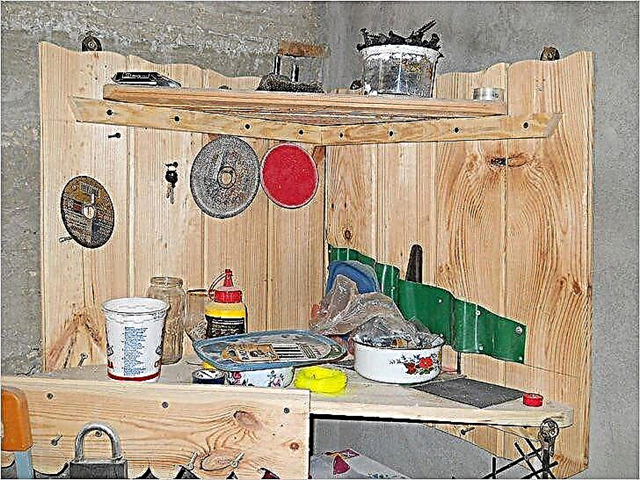

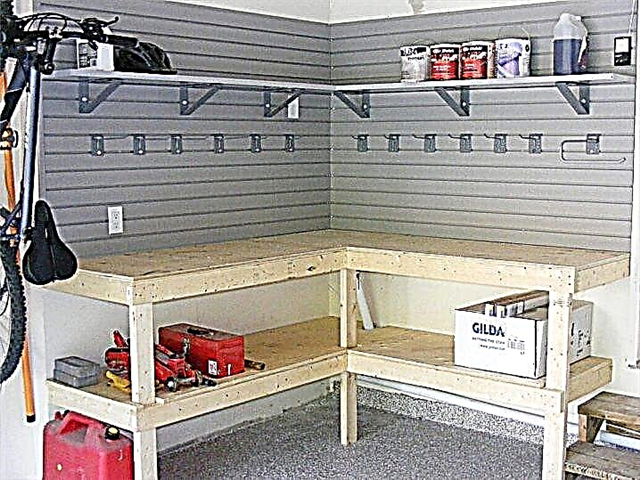

Option for a small garage with a workbench

It's a little harder to choose a product design. The garage is designed for practical purposes. However, this does not mean that its interior should be boring, ugly. In the garage, you can easily make an attractive interior for little money. In particular, you can decorate the design of the rack with ordinary paint. Today there are paints designed for any materials. Color for painting should match the overall color scheme of the room. Colored plastic boxes for storing accessories and tools will become a kind of decoration. They are inexpensive, allow you to restore the perfect order.

Transparent and multi-colored plastic storage boxes for shelves in the garage

Choose material

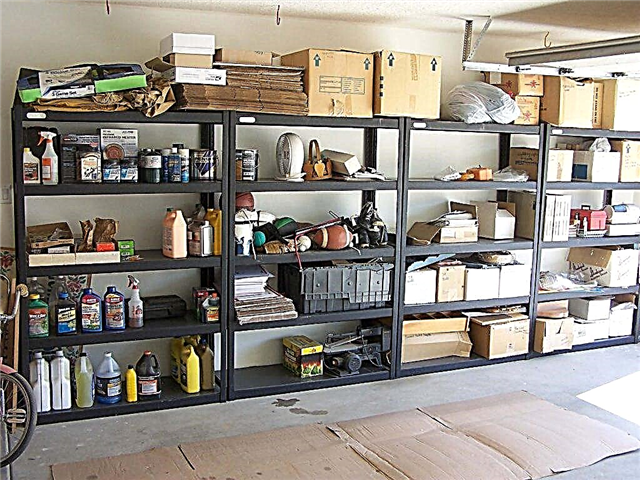

Durable metal shelves in a garage

DIY wooden shelves in the garage

For the design, stability of the frame, the practicality of the operation of the structure, the choice of the main material plays a huge role. The rack can be made from different raw materials, which has its own advantages and disadvantages. Consider the main types of materials, their features in the table.

| Material | Advantages and disadvantages |

| Metal | Many car owners prefer metal for its durability. Such material is durable, can withstand heavy loads. It can only be adversely affected by increased humidity. In normal climates, metal structures will last almost forever. Also, the advantage of such raw materials is the ease of care. Products will need to be periodically simply wiped with a cloth to maintain cleanliness. The main disadvantage of metal is its high price. However, many have unnecessary pieces of metal in the country, friends. Metal elements are usually joined by a welding machine. Using it without proper experience is not recommended. |

| Tree | Wood is a noble, healthy raw material. It makes excellent hanging shelves, racks, storage systems. Wood has a very beneficial effect on the human respiratory system, has an attractive appearance, and is easy to process. In the manufacture of storage systems, you can use oak, pine, birch. Fasten the frame only with metal bolts. Wood is relatively inexpensive. It can be purchased at any building hypermarket. The downside of this option is the difficulty in care. The tree gets dirty, it can get dark, rot. It should always be looked after. This is not always convenient. To reduce such negative consequences, it is recommended to use special impregnations. |

| Plastic | A good option for storing various small items, lightweight accessories. Plastic began to be used to make shelves relatively recently. It can withstand no more than 75 kg. This is worth considering! The advantage of plastic is light weight, mobility, ease of maintenance, low price. The downside is fragility. It is easy to damage, beat. Plastic is not suitable for storing metal tools. |

| Combination of two materials | For example, wood and metal. This is a great option for creating a multifunctional storage system. Thus, you can save, diversify the design of the garage, simplify the manufacturing process of the structure. You can combine almost any type of raw material. |

Metal shelving, collapsible with plastic containers

DIY Benefits

Many people ask a logical question: is it better to make shelves in the garage on your own or to buy a ready-made option on the market? Consider the main advantages of self-creation of a garage storage system.

Folding racks have an aesthetic appearance and are convenient for installation and dismantling

Ability to develop a unique design. For many car owners, a garage is a real pride. I don’t want to put ugly furniture in it. Standard shelves are also not very attractive. In this case, you can take up the work yourself, coming up with a unique design. Ideas for implementation can be found on the Internet. But it is better to unleash your own imagination.

The idea of arranging a garage inside yourself

To make hinged shelves, shelving is not as difficult as it seems. Such a task will be within the power of any man who has at least minimal experience with tools.

The manufacturing process does not take much time. Lack of free time is the main reason car owners buy garage furniture in the store. However, for the manufacture of the storage system does not require huge time costs. It is enough to allocate a few hours, call for help from a friend.

Homemade shelves and racks for the needs of the owner of the garage

Shelves can be made on a personal plan. Only the car owner himself knows what size, depth, height he needs shelves. Find the perfect option in the store is almost impossible. In hypermarkets, everything is standard. It is better to make a little effort, spend time, but create the most practical thing.

Low financial costs. Warehouse furniture is quite expensive. Even the simplest models will cost a large amount. Self-made is the best solution to save money. Many necessary spare parts can be found at your own farm.

Cabinet built into the rack system in the garage

Necessary tools

Essential tools for making shelves

To the process of manufacturing shelves took a minimum of time, you should prepare the tools in advance. It will take not so much: a set of wrenches, pliers, hacksaws for wood, metal, hammer, screwdriver, puncher, jigsaw, grinder. All of these items have almost any good owner. The set of basic materials will depend solely on the choice of each individual. It can be plywood, metal pipes, bars, chipboard, plastic, much more.

Popular garage shelving options

Manufacturing process: step by step instructions

- Preparation of the place of work. Making a shelf is a dusty job. It takes a lot of space. To do this, it is better to remove the car from the garage. Foil should cover instruments, expensive items. Next, you need to prepare the tools, put them side by side. It is advisable to enlist the help of a friend. Together, the work will be completed as quickly as possible.

- Preparation of the plan. For ease of operation, the plan of the rack is better to draw in advance on a simple piece of paper. There it is necessary to note the measurements of each shelf. When preparing a plan, you need to consider specific things that will be stored on shelves. It is not necessary to make a standard design. In one system, you can combine several different elements.

Holders and Mesh Shelves

Installation of mesh shelves on the side of the garage - a quick option for light objects

Shelf manufacturing begins with the foundation

We make grooves for shelves with a milling cutter

We install a shelf in the grooves and additionally fasten with screws

Features

The garage space can be used in different ways, but the general pattern will be the desire to arrange all objects as conveniently as possible so that they do not take up a lot of space and litter the space. Special it is important to keep this room in order if there is a car.

For a car enthusiast, you need space under the car itself, under the wheels to it, tires for winter and summer, repair materials and other useful little things. In addition, usually in the garage all minor repairs are carried out, because it contains all the basic tools, access to which should be as simple and convenient as possible.

The easiest way to arrange everything you need in the garage are shelves of various designs and racks. The convenience of shelves is that they fit in any garage, because they can have different options: hanging, angular, on one or several shelves, wide, narrow, long, small. All this allows us to attribute this element to the most important details, without which the arrangement of the storage area of the necessary things is impossible.

Due to the wide variety of designs and materials from which shelves can be made, it is possible to purchase them in specialized stores or try to build them with your own hands.

The advantage of the purchase option is that you will definitely get a well-made thing and you will not need to make any effort to do this. The positive side in home-made designs will be the choice of material that suits a particular garage, the fitting of sizes to the available dimensions, and the implementation of any version of the product’s designs.

On shelves in the garage you can store a tool that is not too often needed to perform certain tasks. It is important to provide space for liquid products.necessary both for the car and for other works. In this case the shelf may be closed or have a sideso that the container does not turn over and fall from it.

The motorist just can not do without shelves for storing tires with wheels, because this is an obligatory element of the driver.

When planning the manufacture of a shelf with your own hands, it is important to be guided by the basic principles of its placement in the garage - this is safety in operation, so that the dimensions and design are convenient to use and have no risk of injury.

Besides, it is important to correctly calculate the dimensions of this product so that the shelf does not sag, thereby creating the risk of breakdown and falling of all contents on the floor, car or person.

When calculating the dimensions, you need to navigate that more than 15 kg per meter will not fit.

When planning the manufacture of shelves for a garage, it is best to resort to standard sizes - this is a meter or a maximum length of one and a half, width - from 30 centimeters for several tiers and up to 60 for single.

If the area of the room is poorly developed it is possible to foresee fixing additional shelves to those that already exist, Do not fasten the shelves tightly, so that if you wish, you can change their height and location. Given all these nuances, you can independently create convenient and functional storage areas for a variety of things that will be located in the garage.

The main purpose of the shelves in the garage

For Russians, the garage has long become a multifunctional room. This is not just a place for storing and servicing a car, but also a workshop, as well as a warehouse of a variety of things, including:

- car parts,

- wheels

- electric and pneumatic tools,

- oil and gasoline,

- fishing rods and other fishing, hunting and tourist equipment,

- wearable and other things

- food preparations

- detergents to maintain cleanliness.

All this must be streamlined, kept dry and in good condition. For this purpose, there are only two designs: shelving and shelving. The former differ from the latter in that I can be mobile. The shelves are always stationary and mounted on a wall or partition.

For things that are different in geometric parameters, you need a storage place of the appropriate size. In this regard, there are several types of shelves:

- for tools, with rungs to prevent the fall of this expensive equipment,

- for storage of long-lengths: building material such as boards and metal corners, as well as fishing rods, shovels, spare parts,

- for large-sized products: machine tools, heat guns, auto parts,

- for small hand tools, keys, insulating and other materials.

Therefore, the design of the shelves must be selected based on several parameters:

- the dimensions of the items that will be stored on them,

- frequency of use

- weight.

By the same criteria, the location of the shelf is determined and the material for its manufacture is selected.

Types of shelves and possible materials for manufacturing

There are several types of shelves for the garage:

- National teams. These structures can be fully called racks, since it is possible to move them to any place convenient for the owner. They can also be stationary, the frame of which is attached to the wall.

- Suspended, fixed in the subceiling space. They are optimal for storing rarely used things and materials. In the design and manufacture of such structures, special attention is paid to the strength of the fasteners and the ability of materials to withstand significant weight loads. The ceiling, collapsing along with heavy objects, can not only damage the car, but also cause serious injuries to people and animals in the room.

- Mounted. Structurally reminiscent of wall cabinets without doors.

- Rotating Ideal for storing the right little things and often used tools.

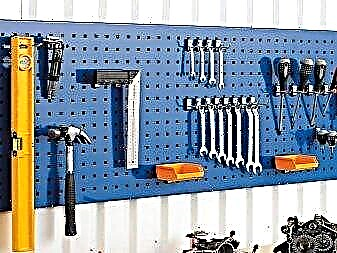

- In the form of a flat shield with many pins for hanging small premes.

- With continuous (monolithic) horizontal surfaces or made of rungs located at a certain distance from each other.

Materials for the manufacture of:

- wooden blocks

- boards

- sheet metal

- metal corners

- pipes of round, rectangular or square section,

- brackets

- metal studs.

Also, for the manufacture of shelves and drawers use items suitable for this purpose: empty plastic cans, flower pots and others, durable and light in weight, containers.

Corner shelf

A metal corner is a reliable material suitable for constructing structures that can withstand significant weight loads. From it you can make a rigid hinged frame for storing wheels. Moreover, the metal must be painted or coated with an anti-corrosion primer. The storage rules of the wheels require you to install them in an upright position, and you can place them at any height, even under the ceiling.

A shelf from a corner can be made in the form of a stable multi-tiered structure, on which it is convenient to store heavy and bulky items. For this, they first of all determine what exactly will be here. The most bulky and heavy items are usually placed on the lower shelf, so the distance from it to the next upper horizontal surface should be significant.

Design + drawing

Corner shelf - a simple design consisting of several elements:

- vertical racks

- horizontal crossbeams of the frame,

- steel or wooden cloths laid on them.

The design process consists of several stages:

- decide what will be on the shelves,

- find the optimal distance between them,

- choose the number of shelves,

- determined with other geometric design parameters: the width and depth of horizontal paintings, the height of the racks.

Advice! The most convenient shelves are 40-60 cm deep and 100-120 cm long.

Manufacturing instruction

Step 1. Using a grinder, cut a metal corner into segments equal to the height of the vertical posts. For a standard design, 4 legs are required.

Step 2. On the wall in the selected place make markings: mark the location of two vertical supports, spaced from each other by a distance equal to the length of the shelves.

Step 3. Prepare pieces of a metal corner for the device of the frames of horizontal shelves.

Step 4. Shelves themselves are cut directly from sheet metal or OSB / plywood. If the dimensions of the frame are 30x1200 or 60x1200 mm, canvases of 288x1188 or 588x1188 mm are prepared, respectively.

Step 5. Assemble the frames in the selected way: by welding or onto bolts with nuts and washers.

Step 6. In accordance with the project, the upper and lower shelves are installed using welding or bolted joints.

Step 7. Attach the structure to the wall in accordance with the previously made markings.

Step 8. Fasten the vertical posts to the wall on the M8 anchor bolts.

Step 9. Install the frames of the intermediate shelves.

Step 10. Lay the prepared canvases of metal or wood onto the horizontal protrusions of the metal corner.

Important! All metal elements are coated with an anti-corrosion primer before starting work.

Wooden shelf

The most common solution for arranging a garage is the installation of wooden shelves. The choice of this option is due to the availability and low price of wood: bars and boards. In order for the design to be aesthetically attractive and safe to operate, all its elements are pre-treated: they are leveled, ground, coated with a fire-retardant composition.

Advice! To calibrate the lumber use a surface gage. With it, you can make all the same structural elements identical in size.

Cable rack shelf

Cable racks, trays, profiles - products necessary for electrical work. From these parts it is possible to assemble a strong and reliable design from several shelves and sections. Also, these products are suitable for the installation of a frame on which wooden, glass or plastic shelves are installed.

The range of auxiliary materials for electrical work includes a full range of fasteners for assembling structures from cable racks. All these products are affordable, are sold in the departments of hardware or wiring materials in any building hypermarket and shopping center.

From cans

A plastic canister is a real find for those who like original solutions for storage systems in the garage. Entire racks are built from these tanks. Canisters act as drawers, one of the side walls of which is neatly cut. Thus, a hollow box with a handle is obtained.

Installation of such racks is simple. In manufacturing, it is recommended to focus on the installation instructions for wooden shelves proposed above. First of all, a multi-section frame is constructed from boards, in each opening of which a canister is laid on its side. Get a convenient, deep, drawer with handle.

Attention! Used cans from under solvents, oils, chemical solutions must be thoroughly rinsed. This will eliminate odor and eliminate the risk of fire.

How can I arrange shelves in the garage

The device of simple devices will significantly improve the usability of storage systems. So, horizontal rails installed along the shelves will prevent accidental falling and damage to objects, injuring legs or hands with heavy tools. Often in garages, racks are overloaded, and when you get one part, you have to move many others. Horizontal jumpers will hold objects within a given space.

The owner’s task is to use the small area of the garage as profitably as possible, while using all available surfaces. For this purpose, angular multi-tier shelves are installed, ideally suited for storing a variety of small things: containers with screws and screws, fasteners.

It is important to place the shelves so that they do not interfere with the free passage, and there is no risk of accidentally bumping against them with your head or hands. An excellent solution is the installation of shelves around the perimeter of the walls at a height exceeding the height of the owner by 20-30 cm. On these surfaces you can store everything that is rarely used, but should always be at hand.

Another option for shelves is to mount a wooden block with a magnetic holder on the wall. It is convenient to fix on it any, small in weight and size, metal products: bits, drills, wrenches, screwdrivers. This is a very convenient way of storage, appreciated by all the owners of garages who used this method of organizing space.

A high multi-tier shelf can act as a partition for zoning the room. In order to prevent things from falling from the rack located in the passage zone, sliding doors are arranged like a sliding wardrobe, or horizontal retaining bridges are installed.

Video: Shelves in the do-it-yourself garage

Without shelves, it is impossible to properly organize the garage space and operate it in the most convenient way. There are many options for arranging storage areas, and you can always find the most suitable for a particular situation. Any shelves, metal or wooden, are easy to do with your own hands. Detailed step-by-step instructions will help.

What materials are used

- steel,

- tree,

- aluminum.

It all depends on where and how you are going to post. If you plan to build a large rack for storing heavy items (such as tires), it will optimally use a steel structure. It will perfectly withstand any weight and will not lose its characteristics even under the permanent influence of dampness and chemically active substances.

For less overweight items, aluminum also works. It does not cope with weight loads as well as steel, but it is fireproof and not afraid of moisture.

Of course, wood has fewer advantages in comparison with metals: it spoils easily, can swell with time or, on the contrary, wither. But if you conduct competent processing of it, then such shelves will last in the garage for a long time, and you will not have to complain about them.

2 nuances that everyone needs to know about:

- to preserve the performance characteristics, the metal used must be galvanized before installation or treated with polymer paint - this will protect the material from premature aging and corrosion,

- if you are dealing with wood, then the mandatory point is antiseptic treatment, which allows you to create a reliable protective layer in case of direct contact with chemically active substances and prevent the appearance of fungus.

Bolt

The trump card of such a shelf is mobility. All parts are bolted together and easily dismantled if necessary. However, at the junctions, even with perfect assembly, a slight play may be present. It is either present immediately, or appears over time under the influence of the mass stored on the shelves.

To cope with the disadvantages of this design can be by fixing it on the walls.

Combined

Usually found in spacious garages and technical rooms for car repairs. It is most often formed by the so-called build-up - when there are more and more tools and storage items, and there is no other place for a new shelf and is not expected.

How to fasten?

Of course, it is up to you to decide, but in garages the following shelf options are most often used:

- suspended - mounted on the wall, the most convenient option for small rooms,

- stationary - created taking into account the layout of a particular garage and can not be disassembled, fixing can be both on the wall, and on the ceiling and floor,

- mobile - recently, more and more often you can meet such an option, at the bottom of such a rack are inserted rollers, which provide the mobility of the structure.

In any case, stock up well with screws and bolts - you don’t need to feel sorry for them, because the main goal when creating shelves in the garage is to ensure reliable storage of even the heaviest parts and objects.

Your procedure

Perform all necessary measurements in the room to determine the dimensions of the future shelf. When working on a drawing, consider the following information:

- minimum recommended height - 37-38 centimeters,

- the maximum depth is 50 centimeters, if more, then there may be difficulties with access to tools and necessary items,

- the lower shelf should be at least 70-80 cm from the floor,

- the span length depends on what is supposed to be stored, but not less than 1.5 m for heavy objects and not more than 2 meters in general.

Choose the type of construction you want based on the material you have. Of course, if you have a tree, you will have to make a non-folding shelf.

Decide on the number of levels in the rack.

Assemble the frame, starting from its base. Attention: we don’t touch the shelves themselves yet, they are installed after the installation of the frame.

Put the necessary markings on the racks, if your structure is placed on the floor, and drill holes to fix the frame.

Connect the elements and install a solid structure. Fix it on the wall if necessary.

And now, insert the shelves prepared in advance and finish the work. You can, for example, paint.

Instead of a conclusion: photos and drawings that will help you

We collected in this section the most interesting, in our opinion, solutions that can fit, including in your garage. For convenience, we divided them into groups: by the main material, by the type of fixation, etc. For the laziest - ready-made drawings that will help to make a shelf in the garage with your own hands correctly and save valuable time. Use it!

Outboard

Drawings and schemes

Tell us about the exclusive shelves from your garage in the comments. Or just about what you did, thanks to our material!

Materials

Thinking about making shelves for the garage on your own, it is important first to decide on the material from which they will be made, which will affect the design of the product itself, as well as the method of attaching it to the surface of the wall or ceiling. So, the most common are metal and wooden shelves.

Metal products most often done using a corner and a steel sheet.

The advantages of this type can be called:

- high strength of the finished product,

- long term of operation,

- stable surface position

- Fortress and readiness for big weight,

- fire resistance

- simple care measures.

There are negative aspects in such constructions, which include:

- the large weight of the shelves themselves,

- the impossibility of mounting on the walls of their cinder block,

- high cost of materials.

If we talk about wooden shelves, then it’s easier to work with them, because they do not require a welding machine and the ability to work with it, and there are many times more options for finished structures. Such shelves are usually fastened with a metal profile.

If we talk about the positive aspects of such structures, then they include:

- light weight of the finished product,

- ease of creation

- neat appearance

- use on walls of any materials,

- low cost of materials.

But in this case, there were some negative aspects associated with the use of wood for the manufacture of garage shelves, which include:

- danger of fire occurrence and spread,

- change in the characteristics of wood under the influence of moisture and dampness,

- systematic work to return the product to an attractive appearance.

In addition, for the garage combined storage areas can be usedthat can be made of several materials at once, it is metal with plastic, metal and wood. There may be separate shelves made of plasticwhich have a diverse appearance and can withstand heavy weight, in addition, they are easy to care for and convenient to mount.

When choosing a metal for work, it is important to remember that it must be coated with a special composition from corrosion, otherwise the product’s service life will be significantly reduced and its appearance will be unaesthetic.

Often metal shelves are chosen for heavy and rough materials.where other material will not serve so well.

If a tree is chosen for work, then it also needs to be coated with special paints that help protect the material from moisture and temperature changes. If this is not done, then after some time the shelves will begin to rot and deform, in addition, such conditions provoke the appearance of all kinds of pests that should not be in the garage.

For both types of structures, you can use chipboard as the shelf itself, or you can choose some good and durable boards suitable width and saw into the required number of parts.

When choosing the material from which the shelves for the garage will be made, it is important to take into account the number of things that will be on them and their weight, as well as the possibilities that will be dictated by the method of work, whether it is welding, or nails.

There is no one true material option for garage shelves, it is important to choose what will be convenient and quick to dothat will last a long time and does not require much care.

Designs and Sizes

As soon as the material from which the shelf for the garage will be created has been selected, you need to think about a design that fits best into a particular room, will be able to accommodate a large number of things, while it will be easy to make and install.

From the whole variety of designs, the main options can be distinguished:

- open type

- closed option

- removable

- made like a frame on which boxes are hung.

Each shelf variant has its own type of fixing system, which is important in the case of walls made of fragile materials or too heavy a structure.

So, there are types such as:

- wall,

- hanging on upright racks,

- ceiling

- single hanging shelf,

- multi-tier hanging shelf,

- stationary structures

- shelves that can be assembled and disassembled,

- structures on wheels that can be moved

- shelves that can be rotated along the axis.

If we talk about wall shelves, they can be open type or have doors. On such structures it is convenient to store equipment that is often used in work. It is most convenient to make them from the corner and mount them to the wall, if possible.

Suspended structures are used in cases where the garage has walls unsuitable for heavy shelves.

For manufacturing, a corner and a wooden base are also taken. To create a side wall, you can take a cable or a profile of rounded metal. Shelves are hooked to the ceiling.

The convenience of such structures is that they can be easily removed if they are not needed, and the drawback is the mobility of the shelves, so it’s not worth putting anything heavy on them.

It is very convenient to build a special shelf in the garage for storing the tool, where everything will be located in its place, in a clear sequence and by occupation.

So, a small wooden surface with holes can be made for screwdrivers, which will include all the products that are only available. This allows you to quickly find what you need. It’s convenient to use hooks for keysplacing the keys on them from the smallest to the largest. Having such a working wall, to carry out any repair work will be simple and convenient.

Ceiling structures can be located against the wall, thereby being not so precarious, as a result of which they can be used for any needs. It is especially good to place unnecessary things in the house. This is a great place for trash, which is often necessary in all kinds of work.

Collapsible shelves of this type are convenient in that they can both be adjusted in height and completely removed if there is no longer a need for them.

If there is no way to hang shelves in the garage, then the rack will be the best option.

He might be:

- stationary

- mobile, where you can’t do without wheels,

- spinning

- collapsible.

When creating shelves for the garage, it is important to use drawings, where you initially need to mark out the type of structure, its dimensions and mounting option. In the standard version, you must use generally accepted dimensions, where the length of the hanging shelf is a meter and the width is 35 cm.

If this is a stationary rack, then its length can reach two meters, and the width can increase to 60 cm. The distance between the shelves usually ranges from 25-35 cm and depends on what exactly will be located on them. The lower shelf needs to be made more voluminous in order to be able to place dimensional and heavy objects on it.

For those shelves that are attached to the ceiling with cables, the optimal dimensions are a length of 60 cm and a width of 30 cm.

The distance between the shelves will be small, only 15 cm, because such storage areas are suitable for small things that are not very often used.

How to do it yourself?

Thinking about making a shelf with your own hands, you need to take the process seriously. Home-made structures must be durable so that they can easily withstand the weight assigned to them and have a margin of safety. The most important criterion for creating storage locations manually will be the safety of the finished structure and its functionality.

When creating a shelf, it is important to worry about its reliability and durability. When making shelving, it is important to choose a size that would allow you to quickly get to any shelf and easily find everything you need. Getting started, it is necessary to decide what type of structure should be chosen and how to fix it so that there is always the opportunity to adjust the height and location of the shelves.

To create a metal shelf, you need to stock up with the materials you need to work.

These include:

- corners and metal profilefrom which the frame will be made,

- welding, with the help of which the cutting of frame elements will be performed,

- shelf material: metal sheets or chipboard, plywood, etc.

In order to build a good shelf or make a shelf, it is important to sketch the future project, and then proceed with its implementation. After cutting all the elements of the frame, you can weld them together or twist them with screws, then lay the shelves and fix everything to the wall with anchors.

If it is decided to make the garage shelves made of wood, then it is important to know the sequence of work and prepare all the necessary equipment.

In the work you will need:

- the bars from which the racks will be made

- plywood or boards from which shelves will be made,

- saw for cutting the main elements,

- grinding machine to give proper appearance to the elements of the rack,

- paint for prevention

- screws or nails

- screwdriver or hammer.

To create shelves or racks in the garage, the first thing you need to do is create a sketch, after which the vertical racks for the frame are cut. The frame is assembled with screws or bolts, after which the boards are laid on it. It is desirable to process the finished structure with a stain, after which it can be varnished or painted.

If there are not enough materials to create a certain type of shelving, we make a combined type of construction. It involves the use of metal and wood or metal and plastic. A very convenient option would be a rack on wheelswhere the base is made of metal, and the shelves are made of wood. In this case, it is also important to do preparatory work with both metal and wood in order to protect them from moisture, temperature extremes and pests.

Hinged shelves are most conveniently mounted on brackets. To do this, make a mark where the fasteners will be made. The installation of the frame is carried out using an anchor, by installing which, you can fasten a wooden shelf using self-tapping screws. If closed shelves are selected for the garage, these may be elements of old furniture for the kitchen or any other room that must be checked before use in a new role. It is best to change the fasteners and install new ones.to protect yourself and protect what will be stored there.

If the garage inside is decorated with drywall with insulation, then shelves can be built as built-in storage areasto be prepared in advance.

There are many options for the location of shelves, as well as their designs, and each one for himself chooses the most convenient option for construction, installation and location.

Tips & Tricks

When planning the creation of shelves for a garage, you need to know some features of the process so that the work is done efficiently and correctly.

If the storage system will be mounted in an upright position, then it is possible to use:

- brackets

- eyes

- threaded rods

- bolts with washers,

- anchors

- furniture canopies.

When choosing the height of the shelves that are supposed to be actively used, it is important to consider the growth of the garage owner. What is located at the level of the chin will be convenient to work with, and what is above this level can be used to store not very important things. It is convenient to use hanging shelves that do not interfere with walking under them to accommodate what is rarely used or takes up a lot of space.

For suspended structures, the supporting elements are located no less than 60 or 70 cm, otherwise the plywood or board will begin to sag and the strength of the entire structure will be compromised.

If you plan to manufacture racks or multi-tier shelves, it is best to use stationary structures or those that are closer to the floor.

If making a storage area would be the first experience in such a business, it is best to start work with wood.

The number of racks and shelves should correspond to what will be located on them. A semi-empty garage, with all the walls in the shelves, will look impractical, as well as one small rack on which tools, tires, and dissimilar things fit.

If any repairs are expected in the garage, It is important to equip an area with tools that are always at hand. A shelf-shield in this case is the most optimal option. There is a place for keys of different sizes and purposes, and for pliers, hammers, screwdrivers, files and other items that are first needed for any small repair.

Good examples and options

In the garage, it is important to arrange a storage place for all contents in order to maintain order and always have access to any object located on a shelf. There can be a huge number of options for making shelves with your own hands, and each has its own advantages and disadvantages.

It is possible to make a rack in the garage even with a shortage of materials, using instead of the frame on the side of the wall, small membranes screwed to the wall, on which the shelf is placed. In this way, you can increase the length of the main surface and place something long on such shelves.

If the length of the entire structure is more than one and a half meters, it is important to strengthen it in front with additional beams on which the shelves will be held.

To organize the working area, you can make hanging shelves on metal corners from above, where you can place the necessary tools, and below, in the form of a small rack, make a work surface, inside which you can also put a lot of necessary equipment, especially with large dimensions.

It will be convenient to organize a shelf-shield between both structures in order to keep the main tool for work in sight.

Shelf-shield can be equipped separately from the workplace, especially if it occupies a large space, or if there is no workplace as such in the garage. With the help of a variety of wooden structures screwed to a metal profile, you can nicely and conveniently arrange everything that should be in any garage.

The combined type of rack can combine the usual open design, on which plastic containers with various contents are placed. It is best to pre-select convenient containers and calculate their dimensions so that the manufactured rack is sized and the contents do not dangle inside and enter too tightly.

Metal shelves can also be combined, where there are not only metal elements, but also shelves made of plastic. It is convenient for storing nails, self-tapping screws that do not rattle on metal and do not scratch it.

The shelves themselves can be from a solid steel sheet or from a grate that allows you not to collect dust on yourself, which means that caring for the garage will be much easier and faster at times, and there will be much more order.

How to make shelves in the garage with your own hands, see the next video.

Which rack is better: welded or bolted

Garage racks are made of wood and metal. For the most part, wooden ones are non-separable - on nails and self-tapping screws. They are usually installed permanently, fixed to the wall. Metal shelving can be welded. Then they are non-separable. There are racks on bolted joints. These designs are mobile, can be disassembled if necessary. Their disadvantage is insufficient rigidity, since there is always some backlash in such a connection. To make the structure more stable, it is attached to the walls. To do this, metal plates with a hole can be welded (bolted) to the extreme racks. Drive a crutch into this hole (having previously drilled a hole of a slightly smaller diameter in the wall).

One option is a frame from a profile pipe and a shelf from plywood

Both welded and bolted racks for the garage serve regularly, but welded structures are more common. The collapsible option is chosen in two cases. The first is that it is possible to move to another garage and all the equipment will need to be transported, and the structure weighs hundreds of kilograms, so moving it around is problematic. The second - there is no possibility or desire to use welding (if the racks for the garage are done by themselves). The rest usually prefer welded ones - they are more stable and, with experience of welding, it gathers faster.

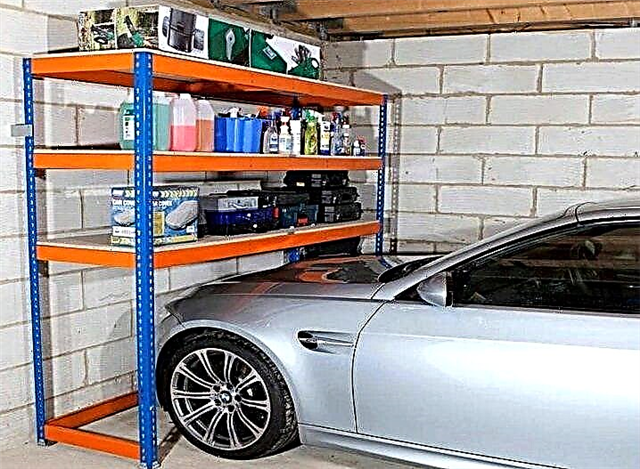

On sale there are also metal shelving from perforated corners. They are also mobile and can be disassembled, but they are connected using hooks (on the cross members) and grooves (on the uprights). Such storage systems are convenient - you can rearrange the shelves to the desired height. Their minus is expensive.

What are they made of

As already mentioned, racks for the garage are made of wood and metal. Wooden ones are lighter in weight, it is easier to work with wood, but they do not withstand such heavy loads. Metal is heavier (heavier at times), but they can be laid and an elephant.

There is still a question of price. Metal rolling is now not at all cheap. If you buy everything at the market or in the store, for the price of you one rack (along with consumables) will cost almost the same amount as the finished one. The only real way to save money is to buy metal at the metal warehouse with whole whips (there are 6 m and 12 m each), and then cut into pieces of the desired length. Cutting can be right at the base, you have to pay extra for services, but the amounts are very small. In this case, you will be able to reduce costs by about 20-30%.

One layout option

Lumber is less expensive than metal. But do not think that the costs will be small: you have to buy high-quality wood without knots, and this is the class of "elite" or "premium" with the corresponding price tag. So it will not work very cheaply.

From wood

The operating conditions in the garage are far from the best - high humidity, frost, alternating freezing / freezing, at times - heat. Not very good for wood. Therefore, all material must be treated with antibacterial and protective compounds before work. Take wood products for outdoor use, as the conditions in an unheated garage are more like them.You can choose a tool that simultaneously tones the surface to be treated and your product can not be painted. After processing, the materials are dried and only after that they begin to work.

How to connect bars

When connecting parts of a wooden rack, you can use standard methods for carpenters - in a quarter or half-hole. If this is difficult for you, you can nail and butt, and to strengthen the joints use metal corners and / or patch plates.

Another point: it is better to connect on nails, and not on self-tapping screws. It turns out more stably, fewer connections "loose". If you choose the option with reinforcing plates, they can be mounted on self-tapping screws.

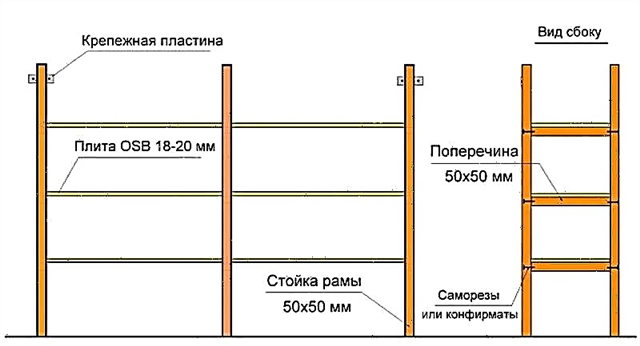

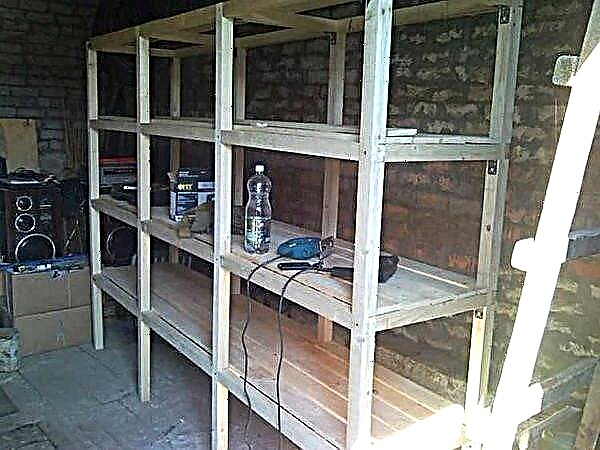

Wooden shelving for garage

Now in size: for racks they usually use a bar 50 * 50 mm, for the crossbars you can use the same bar or a little thinner - 50 * 30 mm. Flooring is made from:

- boards at least 21 mm thick,

- moisture resistant plywood from 10 mm thick,

- laminated particleboard,

- OSB.

The cheapest are plank and plywood. Laminated chipboard is much more expensive, but it does not need to be painted, and this is a good plus. In order not to spend a lot, you can take the first and last sheets in a bundle at the bases - they are scratched and are much cheaper.

Wooden shelving in a garage - drawing with dimensions

Another point: at the shelves from chipboard, a side cut remains open. If it is not processed, with increasing humidity, the chips will swell, the shelf will warp. To avoid this, coat the edges with silicone. With such processing, nothing will happen to the chipboard.

Metal

If you decide to make metal racks for the garage, the choice of materials is wider - there are two options for metal rolling, plus standard solutions for storage facilities (perforated corners). You can also use metal parts intended for other purposes - for example, steel cable racks or cable channels that are used in communication are suitable.

Cable channels and shelves - convenient and not very expensive

So, what does the frame of the metal rack in the garage do:

- From a metal corner with a metal thickness of 3-4 mm. The width of the corner shelf is 25-45 cm - depending on the planned loads. Durable, but metal-intensive material, weighs a lot, is expensive.

- Profile pipe (rectangular in cross section). At lower metal consumption (wall thickness is less), in comparison with a metal corner it has better elasticity characteristics (it is more difficult to bend), more torsion resistant. Approximate dimensions for racks 50 * 50 mm or 40 * 40 mm, on the crossbars 50 * 25 mm or 40 * 25 mm, respectively.

- Racks are made from a pipe, and the cross-pieces from a corner. The thickness of the metal is 2-3 mm, the width of the shelf is 25 mm or more. They unfold a corner so that the laid flooring is like in a “nest”.

Take a close look at how the corners are located

The flooring on the shelves is made of the same materials as for the wooden shelving (board, plywood, OSB, chipboard), only occasionally non-standard options are added that are used with a wooden frame sharply because of the high mass - sheet metal.

Optimal for most regions remains a board - reliable, not very expensive material. It is necessary to take sexually, without knots (with a minimum of knots) with a thickness of 21 mm or more. Treat with antiseptics, then paint.

Plus metal shelves - high reliability with a small thickness, cons - price, weight and "volume". They also need to be painted, only first cleaned of rust, then walk through the rust converter and soil, then - painted and preferably in two layers. Also, by the way, it is necessary to process the metal frame. Then the rack in the garage will not rust.

Layout, diagrams, drawings, ideas

In the garage, you need not only a rack, but you also need a workbench and stand for hand tools - all kinds of keys and other small things, which are many and it’s difficult to come up with a specific convenient storage location.

A workbench can be made in the center of the rack. This is convenient - everything you need will be at hand, you do not have to constantly go to the shelves.

Garage racks with a workbench are convenient

A workbench can be part of the system, or you can make two separate modules, between which set the desired table. If this arrangement is not pleasant, it will be possible to change the configuration - at least put an angle.

As for the tool stand. There is a factory option - a perforated sheet of metal with holders hung on it. The idea is very good except for the price.

As usual, there are several homemade products (what a garage without them) on the same topic. Ideas are simple to implement, maybe not so elegant, but convenient:

- On planks, a sheet of chipboard, plywood, stuff nails under each tool. In order not to get confused where to hang something - circle the tool in place and paint over with some color.

Everything is in order and in place

Option for heavier and bulky tools

It’s not difficult to make this tool stand with your own hands.

And if desired, all this can be put on wheels - to make the stand for the tool mobile. This is the case if in the warm season you prefer to work with the car on the street.

You can easily roll back to where you want

Well, and for inspiration ... so that all the tools are in place))