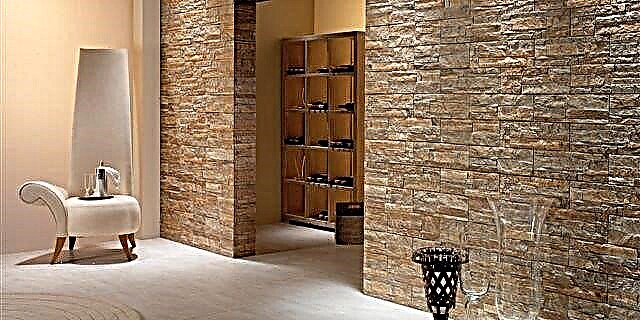

Many people strive to ensure that the apartment or house is not only warm and cozy, but also fashionable, modern, meeting the latest trends in new products. Many building materials are used for the interior of the apartment, including various drywall ideas. If the repair is done with one's own hand, a person’s imagination is endless, and the design of the room sometimes turns out not to be creative, but exciting and extraordinary. The use of gypsum tiles in the interior of the apartment is a design approach that makes the room stylish and modern. Gypsum tile very clearly conveys the contours of natural old brick or sea stone.  Gypsum tile in the bedroom interior

Gypsum tile in the bedroom interior

This causes delight and admiration of the guests. In addition, gypsum tile has many advantages that other finishing materials do not have.

Full content

Rules for selection and scope of gypsum tile

First of all, you need to decide on the question, which tile under which material will most harmoniously fit into your interior. The main task of decorative gypsum tiles is to decorate and emphasize, and not to burden the aesthetic appearance of the room.

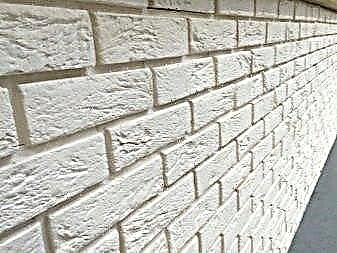

Brick gypsum tile

Since the thickness of gypsum tiles under a brick is small, it is often used in small rooms, thereby saving usable area. The material is used for a kind of background for paintings, the frame of the bar or serves as an excellent decoration of various openings in the wall. It is also appropriate when facing the walls of a large room.

Brick gypsum tile

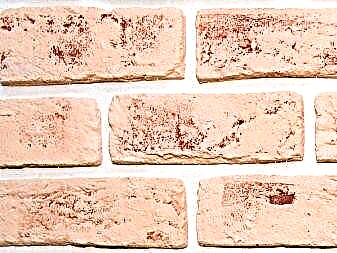

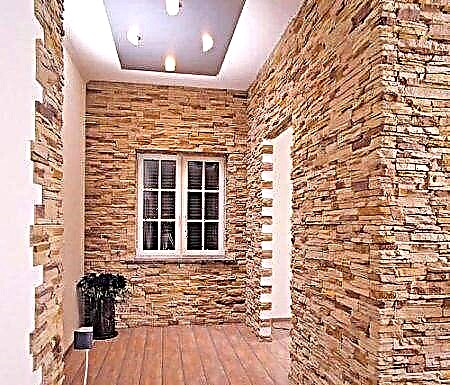

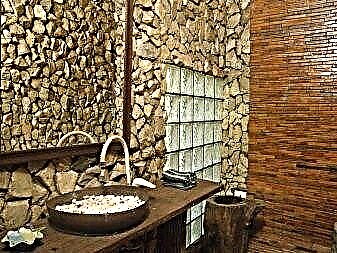

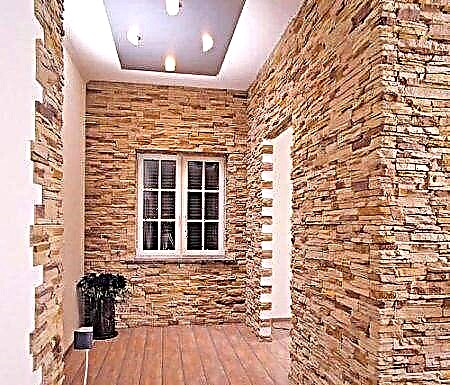

Stone gypsum tile

The use of natural stone as a decor is a good solution. It looks especially good when framed by fireplaces, bar counters, doorways or arches.

More often the material is used to decorate not a whole, but a separate section of the wall. Although on this score, many designers differ.

In any case, there are no special rules and requirements where it is possible to use decorative tiles, and where not. Any hints and advice are only advisory in nature, so the last word is always yours.

Features

Not every apartment can accommodate an additional brick row - buildings in our time are built from metal and concrete, wooden and frame structures have become the norm. Not every design can withstand heavy brickwork. But to refuse such a spectacular design option is not worth it. An alternative can be gypsum tiles, decorated under a brick.

She, like any other material, has certain pros and cons, knowledge of which will help make the right choice.

Advantages:

- Security. Gypsum is a material of natural origin, respectively, products based on it are environmentally friendly.

- Durability. Compared to many other finishes, it has more durability, maintained throughout its life. Often used in places most susceptible to abrasion and mechanical stress.

- Thermal insulation. Due to its low thermal conductivity, it retains heat indoors, preventing the cold from penetrating outside. A wall covered with such material will never freeze.

- Soundproofing. The density of the material is high, the sound permeability is low, respectively, the penetration of noise is minimized.

- Fire resistance. Withstands the burning temperature of a direct flame, it can be used for direct facing of stoves and fireplaces. When heated, does not emit any hazardous substances.

- Maintaining a comfortable microclimate indoors. It absorbs excess moisture from the air, gives it up in case of excessive dryness, evens out the surrounding temperature.

- The ability to create a realistic texture, place accents, emphasize the dynamism of the interior.

- Weight. Gluing can be carried out on any wall without reinforcing using almost any glue, does not bear the global load on the floor.

- Easy installation and handling. You can start work without any experience.

- No need to purchase additional equipment or special materials.

- Cost. Value for money is perfect. The price of the material is low, moreover, there is the possibility of its independent production.

Disadvantages:

- More suited for indoor than outdoor use.

- Excessive hygroscopicity is a contraindication to the placement of the material in street decoration, however, today the production of gypsum-cement slab, which is quite suitable for exterior decoration, has been launched.

- Increased fragility. This indicator can be reduced by adding special substances at the stage of manufacturing and surface treatment after installation.

- Difficulties in leaving. An untreated gypsum surface can accumulate dust.

- When the tile is placed in a room subject to high humidity, it is necessary to process it with additional protective and water-repellent solutions.

Colors

The natural color of the gypsum is white. Initially, the color of the finished product is the same. But in the manufacturing process, it is possible to add coloring pigments of any shade to the mixture. The finished product will be uniformly colored and resistant to fading. With chips and cuts, the cut of the bricks inside will have the same color as outside.

Also, painting gypsum tile is obtained in the process of processing it with compositions from fragility. They contain vitriol, which is a dye. Copper sulfate gives a bluish tint, while iron sulfate gives a yellowish tint.

You can also independently paint it in any color, increasing the possibility of adaptability of the tile to any interior.

How to choose?

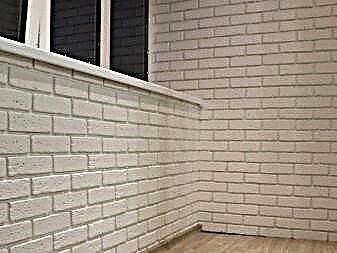

For street decoration, this option will not be acceptable. For the external decor, a similar material was invented - gypsum cement tile, visually indistinguishable from gypsum tile. Therefore, setting out to ennoble the exterior of the home, take the trouble to find out about the composition of the finishing materials in more detail.

Materials imitating bricks are used more and more often for interior decoration. The masonry is perfectly combined with many styles, and in connection with a variety of colors and textures, the question of choosing a specific finishing material is acute.

If your room is made in the loft style, then a large space should be occupied by a brick, at least one wall. The color should be the closest to the color of natural brick - all kinds of shades of ocher-red spectrum. The size of the bricks is selected by a size of approximately 6 by 12 centimeters.

The romance of rural life is best emphasized by the combination of brick and wood. A brick wall could be painted in imitation of lime on top of textured bricks.

The brick goes well with the Gothic style - wrought iron elements and massive furniture, windows with stained-glass windows and a fireplace. Decorative plaster and crystal chandeliers also fit harmoniously into such an interior.

Minimalism is characterized by large masonry areas and a minimum of details. Bright color accents are welcome.

A decorative texture resembling a brick is a worthy alternative to textured wallpaper with a “brick effect”, decorative plaster, drywall, real bricks, and their facing options.

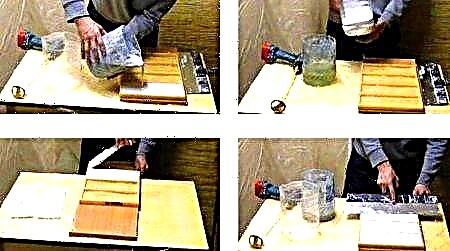

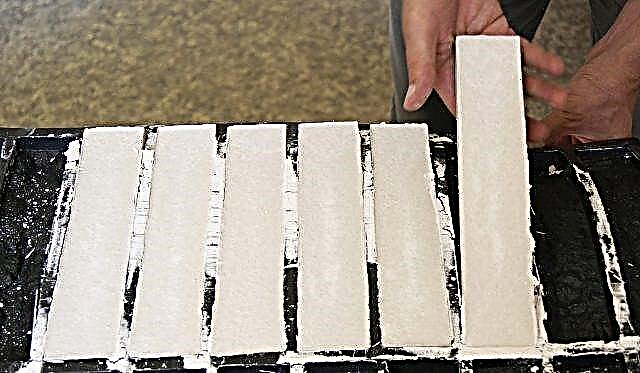

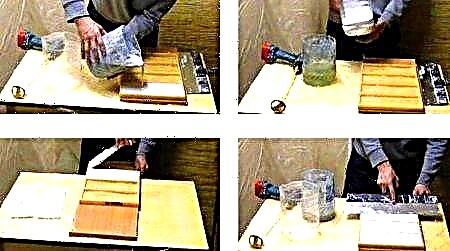

It is possible to make tiles with your own hand. For this, a gypsum mixture, a silicone mold, a flat surface, colors, matte acrylic varnish, brushes and a spatula will turn out to be. If you follow all the recommendations for the manufacture of the product, there will never again be problems with the selection of the masonry fragment you are interested in.

How to stack?

Gypsum tile is quite unpretentious. For its installation, metal, wooden, concrete surfaces, as well as old brickwork, are suitable.

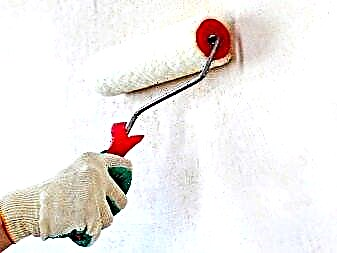

When working with concrete or brick, you must not forget about the porosity of the texture. If such a need arose, they should be treated with a special primer mixture.

If you have to draw up a less solid object, finished with drywall, OSB-plate or plywood board, you need to make sure that these surfaces can keep their shape. Fastening of gypsum decor to drywall should begin after checking for dryness.

Working with wood involves fixing fiberglass to it, which is necessarily plastered. There are two methods for fixing gypsum tiles: dry (fasteners are used) and wet.

Regardless of the method chosen, there is a set of preparatory measures that are fundamental:

- Surface alignment.

- Cleansing of excess substances or contaminants using a soap solution, after which the surfaces will need to be thoroughly dried.

- Now you can directly deal with the manipulation of facing bricks - they should be sorted, excluded defective or beaten copies, laid out for ease of fastening.

Dry laying method:

- Make sure that there are side grooves for fasteners on the fasteners.

- Marking the wall. A distance equal to the length of one tile is laid off from any corner of the wall or furniture. The guide rail is vertically mounted.

- In the resulting "tunnel" is the collection of tiles from top to bottom.

- The decor is fixed using special bolts.

- Repeatedly delaying the length of this element in the neighborhood.

Wet way:

- Determine by which method the bricks will be placed - in the joint or embroidering the seams.

- Marking the rows directly on the cultivated area and preliminary laying out the tiles before fixing them to the wall. We must not forget about the thickness of the future seam, if it was decided to provide for it.

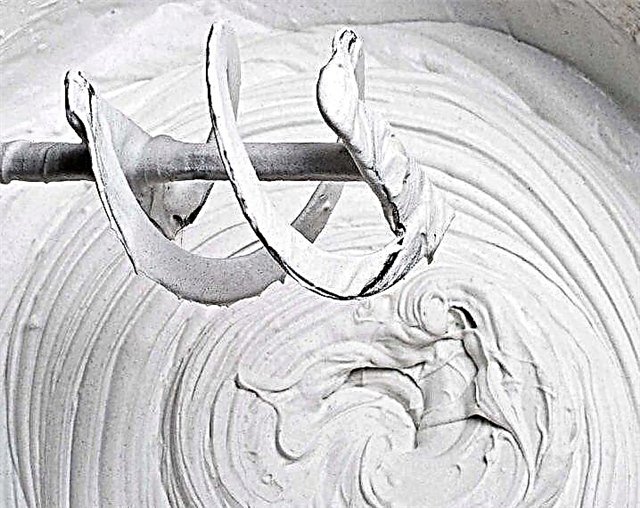

- Prepare a small portion of the adhesive solution, remembering that it begins to set in thirty minutes.

- Work must be done in the direction from bottom to top, starting from the bottom corner.

- The adhesive is applied directly to the tile or to the working area with a thickness of not more than 2 mm.

- The gypsum workpiece is pressed into the wall with a rotational movement very carefully.

Can I paint?

Gypsum tiles with the effect of a natural surface of stone or brick are sold everywhere in stores. The factory method of staining, found most often - staining in bulk. For this, tinting pigments are added directly during the mixing of the gypsum mass. This method is most effective, since when chipped products will have a natural color texture not only outside but also inside.

From a huge number of colors and shades it dazzles in the eyes, but upon closer examination, all the flaws of industrial coloring become visible - tinting is often far from natural and cuts the eyes with strange color accents.

Coloring the finished product - it seems to be not a complicated matter, but the success of the entire design project depends on visual perception. If you set out to bring an element of liveliness to the factory painting and do it for the first time, then it is worth processing each part separately before fixing it to the wall. Subsequently, upon receipt of the initial experiment, one can proceed to the mass painting of the gypsum sheet already fixed on the object.

There are several simple and time-tested methods of painting:

- To half a teaspoon of paint add a glass of water and an acrylic primer. Accent spots are applied directly to the bottom of the mold before pouring the solution. With this method, high-quality drying is required, after which the workpiece is coated with a water-based matte varnish.

- The tinting paste is added to the water and applied to the untreated gypsum surface with a brush, airbrush or a simple household spray. Due to its hygroscopicity, gypsum absorbs paint and after drying it will take on a very lively look. You can replace up to half the water in the solution with an acrylic primer, from which the dried tile will gain additional strength.

If the color becomes too pale after tinting, it can be restored to natural by applying a matte or silky-matte varnish. This will give the product extra strength.

Examples in the interior

Designers around the world are delighted with the prevailing tendency to introduce such an element of decor as a brick wall into the interior of residential apartments, office premises and public institutions. It can be used both in a brutal fireplace room and in a romantic bedroom.

A brick wall can be a great alternative to wallpaper, panels and plaster, because it looks more intriguing. The cost of material imitating a real brick is minimal, and the possibilities are almost endless:

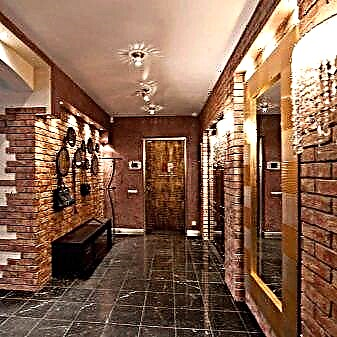

- Hallway Most often, in conditions of limited space of the hallway under a brick, it is customary to decorate only one wall. The light tone of the bricks will not hide the space. Another option is to lay with a masonry a frame for a mirror, an arch, a place for clothes.

- Living room. A brick wall is the perfect backdrop for creating a video zone. Also, it is the best suited for creating a contrasting interior: the dark shade of the masonry is light furniture, and vice versa. Even if the accent brick wall is painted in the same color shades as the rest of the space, it will attract attention with its texture. If the interior of the hall is supplemented not only with a brick wall, but also with massive wooden ceiling beams and columns, the interior is filled with wrought iron objects and crystal chandeliers or sconces, then it will be possible to bring the spirit of a medieval castle into a modern dwelling.

If there is a fireplace in such a space, it is possible to decorate with gypsum bricks not only its firebox and facade, but also the space near and above it.

- Bedroom. The tranquility of the sleeping place will in no way be disturbed by the brick wall behind the head of the bed, and it will look stunning.

- Children’s. In the children's room, the brick can be used as zoning.

- Bathroom. In combination with snow-white plumbing, the brick texture gives an interesting contrast.

- Kitchen and dining room.

- Masonry as a kitchen apron.

- Zoning of the dining area.

- Contrast with monotonous kitchen planes and facades.

- Office and office

- A cafe

See how to make an imitation of a brick wall from gypsum tile below.

Types and distinctive features of gypsum tile

In the production of ceramic tiles, clay goes through several processing methods and the production of this type is rather complicated compared to gypsum tiles. Plaster can be used in the interior of an apartment everywhere:

The tiles can be made to finish the ceiling, interior partitions from the GKL, arches, the entrance to the room, the walls in the kitchen and much more.  Brick gypsum tile

Brick gypsum tile

- Under the brick. This tile completely repeats the brick pattern, whether it is white or old-style red.

- Under the stone. Tiles with the texture of natural stone are not inferior to clear edges, colors.

Stone gypsum tile

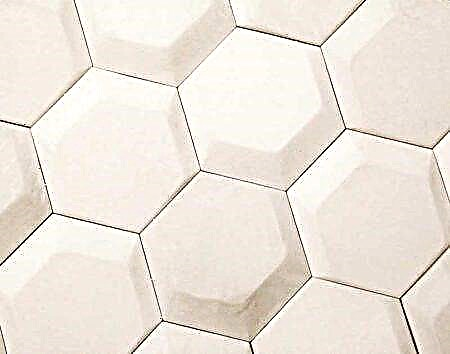

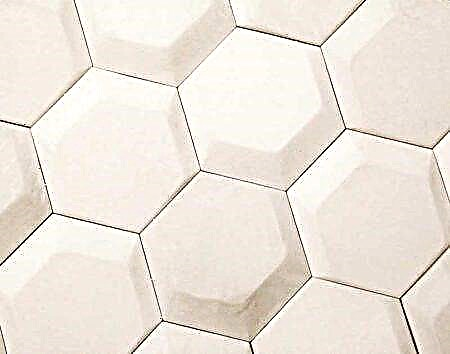

Stone gypsum tile - Gypsum panels. They are lightweight, multifunctional. They have a diverse pattern.

Gypsum panels

Gypsum panels - Sea pebbles or mosaic.

Gypsum mosaic

Gypsum mosaic

Each type of gypsum tile is defined for the decoration of the room.

The positive and negative sides of the tile

All building materials have advantages as well as negative aspects.

Gypsum tile has the following advantages:

- Weight. Tile is a lightweight material. This makes it possible to mount it on many surfaces without burdening the base.

- Installation of tiles on the wall is quick, easy and do it yourself.

- Gypsum does not contain toxic impurities that would be harmful to humans and animals.

- Big choice. Gypsum tile differs not only in textured patterns, but also in colors. And there is also the opportunity to create an individual tile with your own hands with your own color.

- Cost. The relatively low cost makes it possible to make cladding of large surfaces.

DIY tile manufacturing process

DIY tile manufacturing process - Gypsum tile keeps the room warm.

- This material does not miss extraneous sounds.

- Gypsum “loves” water. The large moisture absorption of gypsum tiles may limit the finish in the apartment. For convenience and functionality, the tile should be treated with special means, and after laying it in rooms with high humidity,

- Gypsum tile is soft. If you tap on it with a sharp or heavy object, then it will crack or a dent will remain on it,

- Untreated tiles are practically not washed out. It absorbs dust and dirt, thereby changing color. Therefore, after installation, it is covered with a protective layer of varnish, and during storage, it is carefully closed.

Opening tiles with varnish

Opening tiles with varnish

All negative sides can be smoothed out. Accurate installation, clear actions according to the algorithm of work, timely and accurate care will keep the tile in its original form for many years.

Living room

The decoration in the hall with gypsum tiles is carried out from one wall or partition, while the main finishing material is wallpaper or surface painting. Separate elements - the entrance to another room or the decoration of the plasterboard column emphasizes this element, making the interior of the room diluted from monotony.

Plaster tile in the interior of the living room

Plaster tile in the interior of the living room

But, if you are facing the fireplace with gypsum tiles, you need to arrange color accents. If this is a false fireplace made of drywall - it should not be radically distinguished from the general background, but only emphasize individuality.

When the living room is decorated with gypsum tiles under a brick, you should find the right angle of illumination. With directed light only on this surface, and the whole living room will be in the twilight, there will be a feeling of cold and damp, and not comfort and warmth.

What is it for?

When creating an interior gypsum tile imitating stone or brick, can be used to solve various functional problems, namely:

- with small dimensions of the room, thin tiles take up much less space than natural stone,

- to highlight a specific area with a clear outline, for example, an arch of a doorway or to create a background, for example, for an aquarium, picture, TV and other objects,

- to create a vast surface with imitation of stone or brick wall and to give the interior a certain specificity,

- as covering the walls near the entrance to the room in order to maintain a pleasant appearance - after all, gypsum tiles wear off more slowly than wallpaper or painting, it is also much easier to clean from dirt, and possible chips can be easily repaired with gypsum mortar,

- in the presence of through turns, corners where there is constant contact with the coating. In this case, the property of a tile that is easy to clean will be very appropriate.

Gypsum tiles can be divided into various categories: by type of texture, by type of production, by place of application.

By type of production:

- Factory. This tile is made based on certain conditions of the place where it should be used: for dry rooms, for bathrooms, for facade cladding, etc. It contains special additives that provide the necessary performance properties. Factory-made gypsum tile has passed all the necessary checks and is certified.

- Hand made. Such products can have any composition selected for specific operating conditions. Such flexibility, on the one hand, is a plus, because factory products cannot take into account the individual characteristics of each room, on the other hand, there is no guarantee that home-made tiles will last a long time.

By type of invoice:

- Brick imitation. Gives the room the originality of an unfinished building, brutality and a sense of Spartan conditions.

- Under a natural stone. Such a design will add natural color, the primacy of the cave dwelling, rural or castle motifs of the Middle Ages.

At the place of use:

- For interior work. Tiles for the hallway or corridor will contain reinforcing substances that provide strength to mechanical stress and abrasion. Stamps intended for bathrooms and kitchens will contain additives that enhance the waterproofing properties necessary for long-term service in rooms with high humidity.

- For facade cladding. Such a tile necessarily contains a large number of hydrophobic additives that provide resistance to aggressive weather events: rain, snow and others. Although a hybrid composition based on gypsum and cement is often used. So, although the weight increases, and, accordingly, it should be fixed on the surface with more durable means, the price of such tiles is much lower due to the cheapness of cement in comparison with waterproofing components.

Design

Using plaster tiles under a brick, you can implement a variety of design decisions and at the same time save on material for a similar repair made from natural materials. For example, when decorating large areas on drywall with light tone tiles, the volume of the room visually increases, and vice versa, when decorating with dark tones, it decreases.

Creating a design based on contrasting shades using tiles of various colors is a common solution. Full wall decoration with tiles will create the effect of a dwelling built on a rock or in a mountain. To enhance the already existing decorative elements, such as panels, it is possible to frame the fireplace in order to give it a visible massiveness.

Gypsum tile imitating brick is great for creating interiors in the style of loft, grunge, country. With the combination of gypsum tiles under stone or brick with wooden decor elements, you can create the atmosphere of a country house, even in a city apartment.

Gypsum tile can replace the standard finish of door and window portals with platbands, it looks great when decorating various recesses and niches in the walls, for framing mirrors.

Tips & Tricks

Gypsum tile is a specific material that has both significant advantages and significant disadvantages. Some weaknesses can be modified using special impregnations applied to the finished product, and various additives are added to the gypsum tile at the production stage.

Gypsum is a material with excellent qualities, but it has two significant drawbacks, the bulk of the effort is being addressed. This is fragility and poor moisture resistance combined with high moisture absorption.

To strengthen the product, you can go in two ways: either add special substances to the composition at the time of production, or treat the finished tile with reinforcing impregnations. A dual-circuit option is also possible.

At the stage of creating a mixture for tiles, to increase the strength, substances are added to the composition that affect the properties of gypsum tiles. Accordingly, the effect of them is maximum. So, a tile intended for places where there is constant contact with the finished surface, for example, door portals, corridors, waiting rooms and the like, must necessarily contain components that enhance its resistance to shock loads and abrasion.

Superplasticizers is a group of chemical additives that promotes accelerated solidification of gypsum mortar using less water. Thus, the composition increases the content of the binder, which makes its solidified form more durable. In addition, plasticizers improve the uniformity of the mixture.

Modifiers are an extensive group of substances capable of enhancing various properties of gypsum tiles: strength, resistance to weather conditions, water resistance and moisture absorption, wear and frost resistance.

With gypsum tile already on hand, it is also possible to strengthen its structure by treating the surface with various substances. This effect has an additional effect on the quality of the product, however, it is necessary in cases where the operating conditions of the tiles are particularly aggressive.

Among them are:

- Polymer impregnation. Due to the fact that gypsum is very porous in nature, which determines its fragility, its surface absorbs various substances well. To strengthen the strength, polymer compounds are used, for example, on an acrylic basis.

- Painting. This method helps to strengthen the surface of the gypsum tile, protecting it from scratches and preventing moisture from entering due to the protective layer created by the hardened dye. Often, water-based acrylic varnish is used for this purpose.

- Sulphate treatment. Like polymer impregnation, it strengthens the structure of gypsum tiles, penetrating into the pores of the substance. Both copper and iron sulfate are used. Together with increased strength, the product is given a characteristic shade - copper gives blue, and iron gives yellow. The soaking procedure should last about two hours.

The ability of gypsum tiles to absorb moisture is also modified both in production and can be reduced for finished products. A composition that contains waterproofing additives can already be used for kitchens and bathrooms, but only in places where there is no direct contact with water, for example, it is not recommended to cover it with a bath or the space around the washstand.

In order to use gypsum tiles for facade work, in addition to the substances that strengthen the composition, an external treatment is carried out with hydrophobic impregnation or water-repellent paint.

Beautiful examples in the interior

A brick product can be used not only on small surfaces. They are excellent for cladding large areas.

White brick tiles look stylish. It can become a neutral background for bright furniture.

You can watch a master class on laying gypsum tiles under a brick in the next video.

Finishing Methods

The material in question is an elongated tile, the shape of which resembles one of the projections of a brick. Usually its length is 18-24 cm and its height is 7-15 cm. The thickness of such a gypsum product is 20-25 mm. The manufacturer, in principle, can produce tiles with other sizes.

Gypsum tiles vary in surface appearance and texture. Stand out "bricks" with a matte and glossy surface, as well as imitating the "old" brick. A special view is products with embossed patterns.

Installation of tiles can be done in several ways:

- On the closed area. There is a complete and partial cladding. In the second version, gypsum tile can be combined with other finishing materials (ceramic tiles, wallpaper, decorative plaster, etc.).

- By appointment. Using the material in question, a wall is decorated or individual elements of the interior are highlighted (for example, a fireplace, a window, a door). Tiles can be laid on a wall surface, in niches or on ledges.

- By the method of fastening. 2 main technologies are used: dry and wet. Dry laying involves the use of tiles with a special profile on the edges. Such elements are connected to each other "in the lock" (for example, according to the "tongue-groove" system). With the wet method, the tile is fixed with glue.

- According to the formed pattern. When laying gypsum tiles, an imitation of brickwork is achieved, and therefore all possible options are repeated - spoon and stick, single and multi-row, and other types of masonry. For this, various sizes of tiles or cutting them can be used. Arched and other special types of styling look spectacular.

The choice of finishing method depends on the specific conditions, the chosen design style of the overall design of the room.

How is the facing

Facing the walls with gypsum tiles is performed in the following order:

- Preparation and leveling of the base (wall).

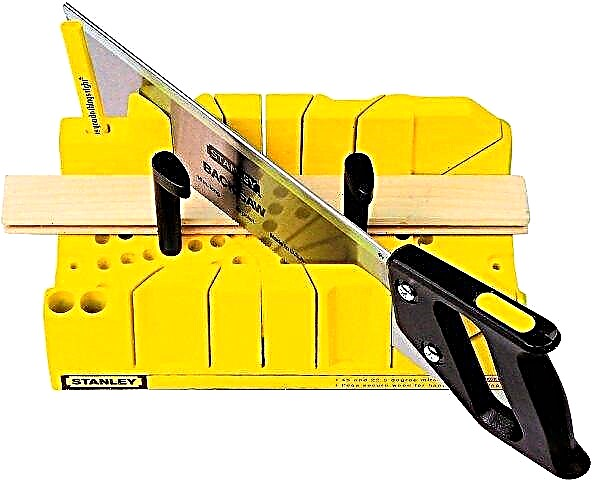

- Training. All items are carefully inspected. Tiles with defects (breaks, deformations, cracks, etc.) are screened out. It is recommended to pre-lay the masonry on the floor. Incomplete elements are prepared in advance by cutting the tiles with a hacksaw for metal or a grinder. The back should be sandpaper for better grip. For porous tiles, the front side is covered with a thin layer of transparent primer.

- Preparation of the adhesive. It is carried out in a convenient container. For uniform mixing, it is better to use a construction mixer. The whole process is carried out strictly according to the instructions for the finished mixture. The consistency should be thick but easy to apply.

- Laying (gluing). It is installed in rows, starting from the bottom. A small gap is left between the tiles.

- Sealing up the seams.

The work is completed by the final finishing of the cladding. Various methods may be used depending on the material and the chosen style.

Surface preparation

To obtain a high-quality finish, an important role is played by the preparation of the surface on which the gypsum tile is laid. This stage includes such works:

- surface cleaning from old coatings and plaster,

- garbage collection, dust removal,

- elimination of significant defects (cracks, dents, etc.) using putty,

- applying a deep penetration primer.

If the wall has significant irregularities, then the surface is leveled. Perhaps the use of such methods:

- lighthouse plaster

- gypsum plasterboard alignment with grouting,

- for small deviations, OSB sheets can be used.

Responsible operation - surface primer. It provides final surface leveling and adhesion of materials. The following primers are used:

- Mineral primer. It is characterized by quick drying and versatility.

- Perchlorovinyl primer. It is used in the treatment of concrete and metal surfaces. It is superimposed in 2 layers. Drying time - up to 1 hour.

- Acrylic primer. The material belongs to the universal category and is suitable for any surfaces.

The primer is applied with a paintbrush, roller or spray gun. The second layer is applied after the first layer has dried.

Marking completes the preparatory phase. It is most relevant for partial cladding and combination with other materials.

Gluing

When fixing gypsum tiles to the wall surface in a wet manner, an adhesive is used. It is selected taking into account the base material, the area to be tiled, the type, size and color of the tile itself.

The following recommendations should be considered:

- Gypsum with cement. Such compositions are realized in the form of ready-made, dry mixtures from which a gluing solution is prepared. They are most suitable for tiles of light shades. The most famous mixtures of brands Perlfix, Litokol K, Satyn PKG-28.

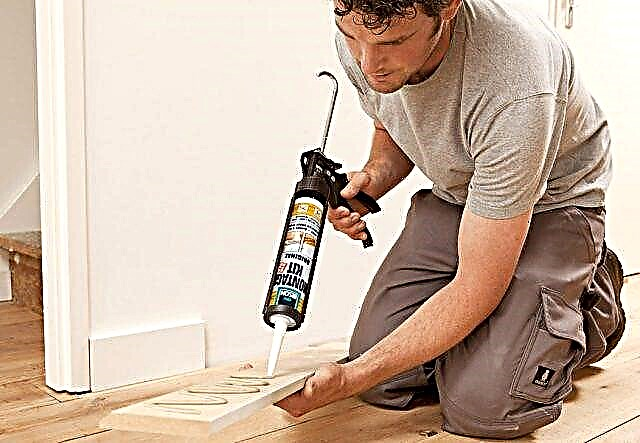

- Liquid nails (sealing compound). A common option is the universal adhesive type "Dragon".Its main drawback is the need to hold each element for 2-2.5 minutes by hand, which delays the finishing process.

- Ready-made, liquid gypsum mixtures. This is the best option. The composition is sold in the consistency of thick sour cream and has a white color. It is easy to apply, holds together well and can be used for any gypsum tile. Holding should be provided for only 2-3 seconds. Full drying occurs during the day, and you can adjust the location effortlessly after 15-20 minutes.

Bonding is as follows. On the back of the tile with a special (toothed) spatula, the adhesive composition is applied in a thin layer with a thickness of about 0.2-0.3 mm. The tile is fixed to the surface and held by hands (usually 4-5 s). An adhesive is applied to the side face to connect with the adjacent element.

The seam between the tiles can be of different widths depending on the selected pattern and the room to be trimmed. Sometimes they overlap when there is practically no seam, but in this case elements of an ideal shape are needed. Most often, a seam is left, the width of which should not exceed 1 cm. The best option is 5-7 mm.

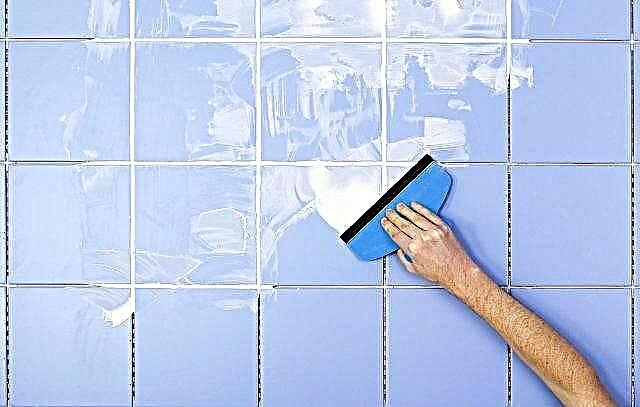

To make the cladding attractive, the joints are filled with special grout. It allows you to mask minor inaccuracies in the installation and edges of the elements. The procedure begins a day after installation, when the glue dries. As a grout, ready-made gypsum putties or glue used to fix the tiles is used.

If desired, you can add the pigment of the desired color to give the mixture a certain shade. Filling is carried out using a narrow spatula, and then the seam is leveled with a bar about 10 mm wide.

The attractiveness of the seam is added by the embroidery. It is produced using a simple tool made of a polymer tube with a diameter of 8-10 mm, which is cut in half in the longitudinal direction. Passing such a grout tool provides a convex shape. The fixed seam is aged for at least 24 hours, after which it is processed with sanding paper.

Final finish

Tile cladding requires a special, finishing. First of all, care must be taken to eliminate the hygroscopicity of gypsum. To do this, the tile is impregnated with water-repellent compounds (water repellents). They are applied with a paint brush or roller.

The water-repellent Tiprom is popular. Other compounds may be recommended: White Hill silicone impregnation, Optimist C405 - Natural Stone silicone impregnation, and some others.

Gypsum tile is decorated by external varnishing. The following options are used for coating:

- Acrylic lacquer. It can be of 3 types: glossy, matte or semi-matte. The varnish is easily diluted in water. After it dries, a thin transparent film forms. The ideal option is the products of the Finnish company Tikkurila.

- Oil varnish. It is glossy and matte. Special solvents are used to create the desired consistency. Colorless (transparent) varnishes or compositions with a certain shade are available.

- Yacht varnish. It provides the most durable coating. Before use, it is diluted with diluent to obtain the desired consistency. Drying time - about 24 hours.

- Shellac varnish. It is made on an alcohol basis. It is widely used for decoupage and giving the tile a certain tonality. You can choose transparent or colored material.

Gypsum tile can be painted. For these purposes, you can use water-based emulsion and oil paint, as well as acrylic enamel.

Painting is done with a brush or with a roller. Paint is applied in 2 layers. On top of it, it is recommended to varnish.

Corner trim

Laying gypsum tiles should start from the corners. Here you need to be careful. In the inner corner, adjacent elements fit closely. The seam is filled with grout.

When forming the outer corner, the abutting edges of the tiles are cut at an angle of 45 degrees. Such an operation is performed using a special tool - a miter box. The slice is carefully sanded with sandpaper. Its surface should be smooth, which allows tight fit of the corner elements.

Framing switches and sockets

In places where sockets and switches are installed, laying gypsum tiles requires a special approach. Their outer cover should fit snugly to the surface, which causes certain difficulties.

When framing sockets and switches, it is important to carefully form a hole (socket) for their internal installation and a platform for securing the cover. The simplest option involves a gap between the tiles in a row.

A wormhole is walled up in it, and the entire space around is filled with gypsum or alabaster with the formation of a smooth platform. In color, such an insert should not differ from gypsum tiles.

Another option is more difficult to implement when the nest is equipped under the tile. To do this, a hole is drilled in it along the diameter of the socket. An electric drill, jigsaw and file are used. The site can be formed in 2 ways. It can be deepened into the tiles.

In this case, a square or rectangle is marked. With a sharp knife, gypsum is cut out according to the marking, and then the material is carefully removed with a chisel to the desired depth. The surface is processed with sandpaper.

You can make an external site. It is formed after fixing the socket. It is better to use a stencil that limits the size of the site. The space is filled with gypsum (alabaster) using a spatula. The surface is leveled and ground.

Possible errors and difficulties

The most important conditions for quality cladding: ensuring strength and appearance. After the glue dries, the tile may just fall off the surface.

This problem can occur if the wall is improperly prepared or the base is not strong enough to hold a heavy coating. Main reasons:

- Excessive porosity of the base. Clay "went" into the wall and did not fulfill its function. This error is explained by poor-quality impregnation of the base and the lack of a reliable primer layer.

- High humidity of the base or the presence of efflorescence on the surface. The wall should be well dried. Areas with mold, fungi and efflorescence must be treated with special compounds and plastered.

- Insufficient base strength. Typically, difficulties arise when facing partitions from plywood or drywall. Before laying the tiles, make sure that the base can support their weight. If necessary, amplification is carried out.

The appearance of the lining depends on the correct installation of each element, the horizontalness of the rows and the uniformity of the seams. To ensure proper installation, it is important to ensure accurate marking and to draw horizontal lines that serve as a guide for the formation of rows.

If the tile lay uneven or shifted, then it must be corrected within 10-15 minutes after installation.

To ensure the uniformity of the seams, cross-beacons (similar to those intended for tiles), installed in the corners of the tiles during installation, allow. It is important to remove all glue streaks from the tile surface in a timely manner.

Costs

Facing walls with gypsum tiles is quite a costly undertaking. To assess the costs, you can give the cost of some products (per 1 sq.m):

- Monte Chiaro A465-10 - from 545 rubles,

- Ellinbrick A-320-70 - from 452 rubles,

- "Old brick" 32010I - from 528 rubles,

- white Loft - from 752 rubles,

- Brooklyn - from 800 rubles.

In addition to the cost of the tile itself, it is necessary to take into account the cost of glue. Its cost ranges from 20-40 rubles / kg, and the consumption is 1.2-2 kg / sq.m. We should not forget about the need to purchase a primer, varnishes, grouts and paints.

How to save

You can reduce the cost of finishing work by making gypsum tiles with your own hands. The cheapest and easiest option is plasterboard “bricks”. They are cut from pieces left over after the construction or repair of the house.

Each element is sequentially coated with putty, primer and plaster up to 10 mm thick. After hardening, such tiles can be used to simulate masonry.

A more complex option is to fill the solution with gypsum (alabaster) in the mold. Silicone mold can be purchased ready-made. You can make it yourself with silicone sealant, sculpted plasticine or paraffin.

The mixture is prepared from gypsum brand GF 10 (5 parts), coarse sand (1.5 parts) and water (2 parts). To increase ductility, you can add a little PVA glue. The ingredients are thoroughly mixed and poured into the mold. You can remove the tile after 30 minutes, and for complete solidification you need 35-37 hours.

Finishing Examples

Different wall designs are achieved in several ways:

- Color scheme. The most popular are white, red, gray, black, yellow and some other colors.

Gypsum tile helps give the interior of an apartment or a private house a special look. It harmoniously fits into various design styles.

You can wall the walls yourself, using the recommendations of specialists. Making tiles with your own hands at home will help reduce the cost of finishing work.

What to look for when choosing a tile

When picking gypsum tiles yourself, it is very important to pay attention to the following characteristics:

- The material must be made of high-strength gypsum brand G-16, G-19 with the addition of plasticizer. Check this information with the seller,

- If possible, arrange the tiles a little check. Try to break one tile with your hands, if this requires a minimal amount of effort, then this option is definitely not yours. You can also rub the reverse side of the tile on a rough surface, while the gypsum should not crumble,

- Color saturation is also important. Too bright indicates that the tile most likely passed surface coloring and no pigment substance was added to the composition. Such a tile will lose its original beauty over time, fading in the sun. It is better to entrust the desired shade to experienced colorists who use high-quality paint and professional equipment for this.

Advantages and disadvantages

Probably there is no such building material that would have absolutely no drawbacks. Let's try to weigh the pros and cons.

Advantages of gypsum tile:

- 100% eco-friendly. Created by nature itself, it is one of the oldest building materials used by our ancestors at the dawn of the formation of civilization,

- Very easy to process. To work with it does not require special equipment,

- Great soundproof material. A wall completely decorated with gypsum tiles absorbs 40% more noise.

- Not afraid of fire. Gypsum can withstand temperature 800° C throughout 5-6 hours

- In the absence of external factors capable of destroying gypsum masonry, it serves above 100 years old,

- The light weight of the material allows it to be used in the design of thin walls without reinforcement,

- The ability to absorb moisture allows you to adjust the microclimate in the room. Due to the porous structure, the accumulated moisture comes out when the air becomes too dry,

- The relatively low cost of the material allows it to be used even by people with a small income,

- It’s almost impossible to distinguish gypsum tiles from natural stone,

- Low thermal conductivity of gypsum 0,261 kcal / m deg / hour. allows you to keep the accumulated heat for a long time. Such a wall will always give warmth and create home comfort.

Disadvantages of gypsum tile:

- Work with gypsum tiles requires utmost care, as the material is quite fragile,

- Without special treatment can not be used in rooms with high humidity.

Tile wall marking

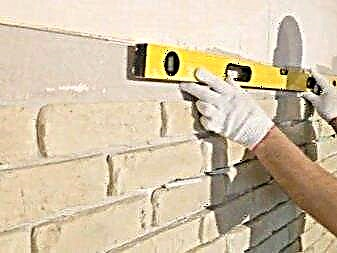

Depending on the tile used, the layout will be different for each. For example, a method of laying gypsum tiles imitating a brick requires a seam.

In this case, using the construction level, draw three horizontal lines from below, leaving a distance of 2-3 mm from the bottom. from the floor. The height between the lines should equal the width of the tile plus the seam.

After three rows are laid out, you need to make sure that the marking is done correctly and visually everything looks exactly. If there are no comments, mark the rest of the wall with the same step.

Marking for gypsum tiles imitating natural or, as it is sometimes called “wild” stone, is made according to the same scheme. Only instead of three lines one is drawn, since the tile is laid seamlessly. The first row will be a guide and level for the rest.

How to choose a good glue

Here, as they say, the taste and color of glue are not. Today, the market offers just a huge selection of different adhesives (silicone or acrylic adhesive sealant, gypsum mixture with PVA, polyurethane foam, etc.) However, experts recommend special gypsum adhesive or putty.

Such glue is applied on the wall and on the base of the tile, due to which adhesion to the surface occurs more efficiently.

In addition, the soil impregnation of gypsum tile, which we talked about a little higher, simplifies the masonry process even more, as this significantly reduces the effect of capillary absorption.

Before kneading, make sure that the glue contains no solid lumps. If available, sift the dry mixture through a fine sieve.

Stitching

- Stitching has a dual function. First - giving the decorated wall a finished, aesthetically attractive appearance. Second - protection of the masonry from destruction, grouting will prevent the possibility of moisture, which could lead to delamination of the tile.

You can use grout from different manufacturers, the approximate composition is the same for everyone. You can buy both white and color.

- Using a regular plastic bag or a special gun, fill all seams to a thickness 5-6 mm

- After the composition begins to dry out a little, with a special spatula, smooth the seam so that it has a perfectly flat surface.

- Allow the grout to dry completely, remove any residue with a dry cloth or brush.

Plaster tiles under brick and stone today is an attribute of almost any design repair.

We hope this material will be a good help if you decide to make repairs on your own and decorate your interior with such a popular decorative element.

Stone gypsum tile

Stone gypsum tile Gypsum panels

Gypsum panels Gypsum mosaic

Gypsum mosaic DIY tile manufacturing process

DIY tile manufacturing process Opening tiles with varnish

Opening tiles with varnish