Along with such brands of manufacturers false ceilingssuch as US firms USG and AMF, OWA from Germany and Ecophon from Sweden, spin off Armstrong from the United States. It is engaged in the production of modular and suspended ceilings, as well as mineral fiber boards for the decoration of ceiling surfaces. In addition to these companies, there are other, less well-known manufacturers of ceiling decoration materials from China and other countries that only occupy their niches in the construction market.

As a rule, Armstrong false ceilings and other similar finishing materials are used in office and commercial premises, but there is no prohibition to use them for decoration of residential apartments.

Advantages and disadvantages

Armstrong suspended ceilings, like any other finishing material, have their drawbacks and advantages. The positive qualities include the following:

- simplicity of installation work. Armstrong suspended ceiling consists of a frame and finishing plates installed on it. All this can be easily mounted independently,

- quick repair. Armstrong ceiling tiles are easy to dismantle and, if necessary, replace,

- heat and sound insulation. Armstrong ceiling panels retain heat and prevent noise. Sometimes during installation, additional laying of noise insulation materials is carried out,

- a large selection of decorative elements. Manufacturer Armstrong produces panels of various colors with a variety of patterns. You can even pick up mirrored slabs for the Armstrong ceiling,

- wide range of components,

- low flammability. Ceiling tiles are made of low-combustible materials that are not flammable in case of fire,

- It does not attract pests at all - insects, rodents, mold, therefore it is safe for use in any premises.

These specifications explain the great popularity of Armstrong ceiling finishes.

But there are some minor flaws:

- installation of a false ceiling Armstrong requires at least 25 cm of space, which makes it impossible to install it in apartments with low ceilings,

- inability to retain moisture. The Armstrong ceiling device does not allow creating an airtight surface, and when moisture gets on it, water flows into the room.

Minor flaws do not really spoil the technical characteristics of the ceiling finish, and Armstrong-type ceiling remains one of the most popular for inexpensive and stylish decoration.

A Little About Armstrong Suspension Features

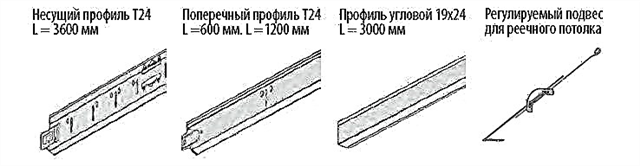

Armstrong suspended ceiling device is extremely simple and consists of:

- bearing profile. These beams support the entire weight of the structure, and their thickness is selected in accordance with the size of the room,

- transverse profile. It is necessary in order to fix Armstrong ceiling panels,

- angular profile. It is necessary to fix the tiles on the corner joints.

All Armstrong ceiling tiles are available in standard sizes in two versions: square and rectangular. Armstrong suspended ceiling design allows for the replacement of individual elements. If there was a desire to update the interior or there was a need for repair, you can only change the slabs of the suspended ceiling, without touching the profile. To do this, just remove the Armstrong ceiling tiles that are bored or unusable, and install new ones in their place.

The standard size of the plates greatly simplifies the selection of material for replacement and allows you to quickly change the design of the room. The fastening is carried out using a spring-loaded knitting needle, which allows, when the final assembly of the Armstrong ceiling is carried out, to obtain a flat surface.

As can be seen from the description, the installation of suspended ceilings of the Armstrong type is extremely simple, and its installation is available even to novice masters.

What are the plates made of?

The company's plants are located throughout Europe, and in Europe have long sought to produce exclusively environmentally friendly products. Armstrong ceiling tiles are positioned as environmentally friendly, as partly made from processed products, and partly from natural materials.

The composition of the tiles includes:

For the final aesthetic finish, water-soluble dyeing or cloth pasting is used.

Armstrong never uses asbestos in its products.

There are so-called soft and hard types of plates, which differ in the percentage of mineral wool. There are more “soft” minvats than “hard” ones, they are more porous and lighter, they absorb sounds better.

Prima

Armstrong Prima ceiling is characterized by high strength characteristics and high moisture resistance. Armstrong ceiling panel from this series is very diverse in appearance and colors. Manufacturer Armstrong offers the consumer not only smooth surfaces, but also ribbed or with a convex pattern.

Designer

Custom-made Armstrong ceilings are expensive, but help emphasize the individuality of the room. The installation of Armstrong ceilings, created on an individual project, is more often practiced in the VIP rooms of cafes or restaurants. But the design personality refers only to the appearance and pattern of the tiles - the installation scheme remains typical.

Individual projects are often complemented by various original lamps for overhead lighting, allowing you to create the right atmosphere in the room. With standard kits, small lamps or wall lighting are recommended.

Armstrong ceiling systems are selected according to their properties taking into account the purpose of the room.

Training

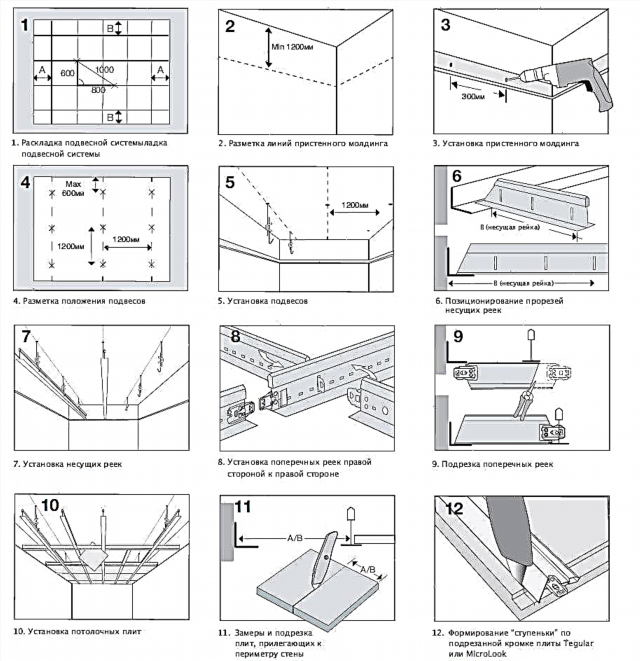

Installation of the ceiling Armstrong begins with measurements. Armstrong False Ceiling Installation Instructions recommends:

- if the floor is level, then measure the height of the room in the corners. The smallest height indicator will become the main. If the floor is uneven, then at work it is recommended to use the building level,

- measure in the selected corner from above 15 cm (if the installation of the Armstrong suspended ceiling is accompanied by additional laying of communications above it, for example, ventilation, then the distance should be increased),

- mark the level in the remaining corners of the room. It is recommended that you use a laser level that allows you to make the most accurate markings in order to correctly install Armstrong false ceilings with your own hands.

Having decided on the height, it is necessary to determine where the suspensions for the Armstrong ceiling will be mounted.

To do this, you need:

- calculate the center of the room. The easiest way is to pull 2 diagonals from the corners, and the center will be at the intersection.

- a line is drawn across the resulting point across the room. With the wall, it should form a right angle,

- 1.2 m is measured on both sides of this line and a mark is made, then the distance is measured again and so on to the end of the wall. Based on these marks, the supporting profile of Armstrong suspended ceilings will be fixed.

The step-by-step description of the marking work before installing the design seems very long, but in fact the marking is done quite quickly. If we neglect the exact implementation of this stage, the Armstrong mounted system can be fixed unevenly, distortions will occur, and the installation of suspended ceilings will be of poor quality.

Installation phase

It is very important that the installation diagram of the Armstrong ceiling is fully observed. The step-by-step implementation of all points of the instruction serves as a guarantee that installing the Armstrong ceiling with your own hands will work out qualitatively.

You must do the following:

- mount knitting needles for fasteners. To do this, holes are drilled according to the measurements applied to the wall and spring-loaded spokes are fixed to them with screws or dowels. To simplify the work, it is recommended to fix the needles with hooks in one direction. Fasten the supporting metal profile to the hooks,

- assemble the frame. The manufacturer for the assembly of the ceiling Armstrong with his own hands provided for special marking on the supporting and transverse profiles. Installation recommendations advise fixing 5-6 main elements on the wall, and mount the cross members on them and then fix the remaining main beams. This method of assembling Armstrong suspended ceilings will save time and timely detect distortions that have arisen due to errors when applying tags. If the skew is slight, then it can be adjusted using spring-loaded mounting spokes. The last metal profile is always fixed close to the wall, regardless of the distance to the previous beam,

- after all the elements are installed, you need to snap the locks in the grooves. This is the easiest step - if the base is mounted correctly, then the locks snap into place without difficulty,

- Now you can set the corners. They are necessary so that the tile square is placed evenly.

If you plan to install fixtures, the basis for their installation must be strengthened with additional crossbars and a plumb line. The more massive the lamp floor, the greater should be the increase in strength.

But it is not recommended to hang massive chandeliers, although Armstrong ceiling installation technology provides for this type of lighting. A heavy chandelier can only fit into an individual project, while typical Armstrong plate materials will not work well with a massive lamp.

Finish finish

How to mount decorative tiles? Perhaps this is the easiest step in the instructions on how to make Armstrong ceiling yourself.

To do this, you need:

- wear clean gloves. Most materials for tiles are very easily soiled, they easily leave traces of traces,

- a tiled square is taken and diagonally pushed into the finished metal cell,

- in the pre-ceiling space, the tile unfolds horizontally and falls face down,

- these actions are repeated as many times as necessary.

That's all, now you can admire the work done. But so that the finish is flawless, the masters recommend:

- carry out work with a humidity in the room of not more than 70%,

- closely monitor the coincidence of the picture. If the embossed version or convex pattern is selected, then the match should be 100%. If an error occurs, it’s worth immediately correcting the error by simply lifting it slightly and turning the tiled square,

- if the tile does not fit in the corner or near the wall, then you can give it the necessary size using a regular sharp knife (scissors are not recommended - they can mash the slice of the plate).

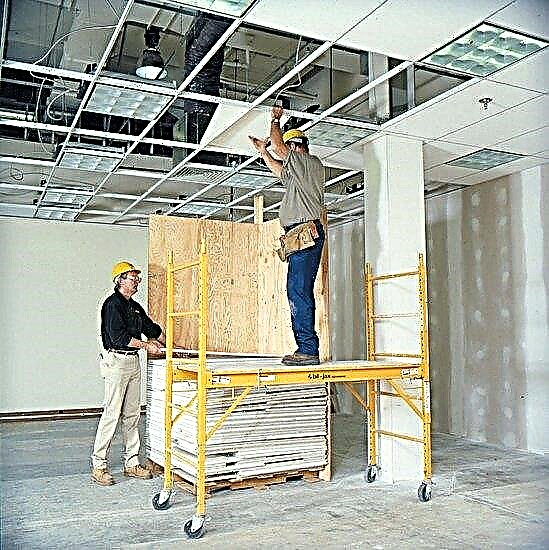

For those who have once installed the Armstrong ceiling, the installation technology of the structure seems extremely simple. For her, no special tools or equipment are needed. With installation work, subject to all stages of the instructions, two beginner masters can handle it.

The only thing that prevents Armstrong products from gaining popularity is that the installation reduces the height of the room, which is unacceptable for many apartments.

Advantages and disadvantages of these ceilings

Positive sides:

- This mineral suspended ceiling will make it possible to always have free access to the ventilation system, as well as to various sensors and lighting fixtures.

- The suspension system will hide all the bumps, dirt and other errors on the base ceiling.

- Quick installation and disassembly, easy maintenance of the ceiling - these are two other significant advantages.

- High light reflection of the plates allows, to some extent, to save on electricity.

- Good absorption of extraneous noise makes this design a great option for the office.

- A large number of accessories manufactured specifically for these ceilings makes installation even easier. In particular, ventilation grilles and built-in lighting elements can be purchased.

- Do not forget that the natural material of the plates is safe and environmentally friendly.

However, Armstrong ceilings are not without drawbacks:

- The main trouble is that they really do not like floods from neighbors from above. After all, even if the plate is moisture resistant, then it does not have water resistance at all. Therefore, if you are not sure about the neighbors or the quality of the pipes, it is better to abandon the suspended ceiling. Take rack or cassette.

- Where temperature or humidity often changes, mineral plates quickly deteriorate. Their color changes - for example, from white it becomes yellowish.

- These plates are quite fragile. They do not like sharp blows, being damaged even from a shot by a cork of champagne. Therefore, you should always keep in stock two or three plates. After all, replacing them is very simple.

Types of false ceilings Armstrong:

#1. Economy class ceilings (types - Baikal and Oasis) are very in demand. After all, this is a minimum of costs and a maximum of convenience. Such plates are inexpensive, but have high quality and decent design.

# 2 Functional ceilings (Prima type) have additional protection against moisture. So, these plates do not change their shape even at a humidity of ninety-five percent.

# 3 Acoustic ceilings (Ultima type) have protection against external noise.

#4. Hygienic ceilings (Bioguard type) are coated on top with a special composition that protects them from the effects of hot steam and fat sticking. In addition, this coating prevents bacteria from multiplying.

#5. Design ceilings have an original look. They are used to give a particular style to any room.

Plates for false ceiling Armstrong

The basis for the slabs used for Armstrong ceilings is mineral fiber (otherwise, stone wool specially processed in a special way). Additives made from latex, starch, gypsum and cellulose (obtained from recycled waste paper) are introduced into this fiber. The technology, worked out to the smallest detail, allows to obtain high-quality material with a minimum of energy and raw materials costs.

Cheaper boards have more starch, while more expensive ones have more latex. This additive gives the material excellent moisture resistance.

Finished boards are laid with sheets of cardboard, stacked and sealed in polyethylene using vacuum. Thus, the material receives protection from natural disasters and mechanical damage. A stack may contain eight to twenty-two pieces. In the latter case, the packaging is enough for 7.92 square meters of ceiling.

It is necessary to store and use the plates under certain conditions: humidity is not allowed more than 90 percent, and the temperature limit is even less - from 15 to 30 degrees.

To make installation more convenient, Armstrong mineral plates are produced with three types of edges:

- Slips with a Microlook edge have a not very wide stepped edge. They are used in suspended structures with a width of 1.5 centimeters.

- Tegular edge plates also have a stepped edge, but wider. They are used in suspension systems with a width of 2.4 centimeters.

- Board slabs are universal - their edge is even, therefore, such slabs are suitable for both types of suspended structures.

As for the other characteristics of Armstrong mineral slabs, they are as follows:

- Width - 60 centimeters,

- length - 60 or 120 centimeters,

- thickness - varies from 0.8 to 2.5 centimeters,

- weight - from 2.7 to 8 kilograms per square meter.

What is a suspension system?

The popularity of using precisely ceilings from mineral slabs is due to several factors. In particular, it is ease of installation and low cost. Well, the technical specifications of Armstrong suspended ceiling also play a role.

By and large, there are two main types of such systems: modular and continuous. Often the first type is used, which consists of a frame and modules - panels, cassettes, rails. The frame is usually hidden under the roof lining. However, there are options when this is not required, and then its protruding elements are visible. Unlike a false ceiling, a suspended system takes up more space. But under it you can hide any engineering communications.

By the way, the installation of this ceiling must begin precisely with the conduct of communications (otherwise it will be difficult to do this later). Next, a frame of transverse and longitudinal profiles is attached to the ceiling base. The distance between the individual profiles is 60 centimeters (this is exactly the size of Armstrong mineral plates). By the way, the installation of the frame is very similar to the installation of the supporting structure from drywall. The last stage of work is the installation of stoves, ventilation grilles and lamps. It will not be difficult - the assembly of the ceiling is similar to the assembly of a children's designer.

About the aesthetic component

Perhaps the favorite of all the colors used for the ceiling can be called white. But on sale today you can find both colored and patterned plates of Armstrong. And black ceilings are often used in cinema halls. Differ plates and texture. In addition to the most commonly used smooth ceilings, there are perforated as well as embossed ones. There are also cells of the open lattice type, which look very interesting. In addition, they are able to visually hide the entire suspension system.

Such a variety allows you to design the ceiling completely to your liking. You can vary the number of levels. This will allow you to get very interesting effects in the office, apartment or public premises. Using the built-in lighting elements, get beautiful three-dimensional designs. At the same time, the suspensions are hidden or left in sight.

Where to use Armstrong ceilings

Different types of premises have different operational requirements. This must be taken into account when choosing a suspended ceiling. And there is such an opportunity - as mentioned earlier, as many as four types of Armstrong mineral plates are produced, each of which is suitable for certain conditions.

#1. The universal economy-class ceiling does not stand out by any features, therefore it is suitable for normal operating conditions. This, for example, may be the premises of industrial buildings, hotel halls, schools and kindergartens.

# 2 A functional ceiling created from moisture resistant panels (which contain a lot of latex) is needed where the humidity is very high. For example, it can be the premises of a store, cafe or restaurant, a swimming pool, a bathroom in a house, a bathhouse, and laundry. Also, such ceilings can be installed in wet workshops of industrial enterprises and where there is direct access to the street (in corridors, halls).

# 3 An acoustic ceiling is necessary where it is necessary to muffle loud sounds. In particular, it can be a cinema hall, office or night club. Such characteristics of the Armstrong ceiling are also suitable for a hotel or a noisy production room.

#4. The hygienic ceiling is specially designed for medical and food facilities. Complying with all the norms and requirements of hygiene, such products adorn hospitals with outpatient clinics, as well as workshops of food enterprises.

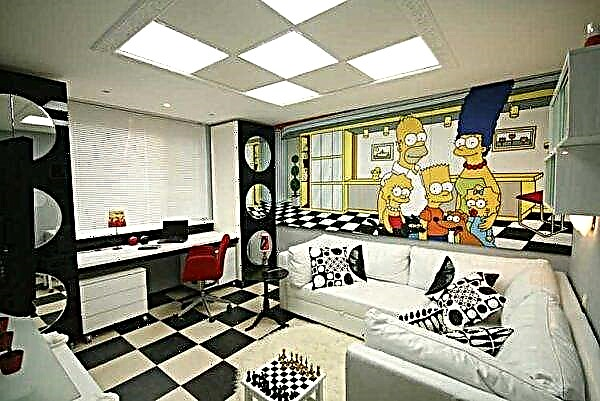

#5. Designer ceiling shines not with technical characteristics, but with its shape and color. It is needed where exclusive and originality is required. This can be, for example, a store hall, hotel lobby, office or restaurant. It is possible to make a public space unusual, or you can pamper your own apartment with a designer ceiling.

System device

Armstrong suspended ceiling consists of a system of profiles, with the help of suspensions attached to the draft ceiling. These profiles form square or rectangular cells in which fixtures and boards are installed. All this together is the Armstrong ceiling system.

Armstrong ceiling - one of the options

Profiles are bearing (guides). It is they through the suspensions that are attached to the draft ceiling and carry the main load. The total mass of the entire system is small, therefore, guides are installed through 120 cm. Suspensions are mounted along the marked lines in increments of 50 cm. In their lower part there are hooks, and in the guides there are holes. Guides are simply hung on hooks. After that, we got parallel guides placed in increments of 120 cm.

Armstrong ceiling device

Between them with the same step - 120 cm - a transverse profile is installed. As a result, we get a cage of 120 cm * 120 cm. Armstrong suspended ceiling plates have a size of 60 * 60 cm (to be precise, 598 mm * 598 mm). For their installation, frame profiles are still attached - so that a cell with the required dimensions is obtained. After that, it remains only to mount the fixtures and install in the slab cells.

System elements

Armstrong ceiling system consists of a set of elements that are easily interconnected. One of its advantages is its modularity, which allows you to get a ceiling of any size and configuration. The problem is only with non-linear forms - they are not provided and there are no standard solutions. Therefore, this type of suspended ceiling is used only in square and rectangular rooms.

This is a mixed-fill Armstrong ceiling option.

Profiles

Armstrong ceiling profiles are made of light aluminum alloy. Perforation is applied to the upper part of the profiles, with the help of which they are attached to the suspensions and joined together. The lower part of the profiles - the one that is visible from the room - may have a silver color, but more often - white. There are also black and gold, you can find other colors, but they must already be sought.

Most often profiles are painted white

The length of the profiles is 600 mm, 1200 mm, 3600 mm. Bearing profiles must be solid (in case of need, they can be spliced), therefore we select the length so that the profile is not shorter than the room. It is cut into sections of the desired length.

You type transverse profiles partially 120 cm long, partially 60 cm. You will have to consider how much you need to create any kind of suspension system in your case. Cutting them will not work - ledges are made around the edges, with the help of which they are joined with the carriers.

Armstrong ceiling installation diagram and its components

Bearing and transverse profiles come in two sizes - for different types of plates: with a shelf of 15 mm and 24 mm. There is a different “back” - for different thicknesses of plates (19 mm, 24 mm and 29 mm).

There are also wall profiles. They are made in the form of a corner, mounted around the perimeter of the room. The extreme plates rest on them. They also have shelves of different sizes - 19 mm and 24 mm.

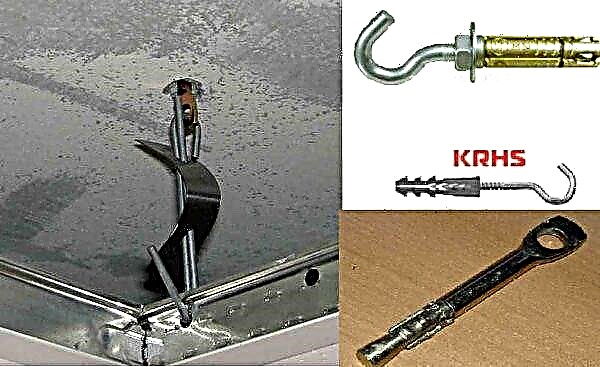

Suspensions and how they can be replaced

Armstrong ceiling suspensions have a hole in the upper part for installing fasteners, and in the lower part there is a hook that holds the profile. The upper part is attached to the ceiling using dowels or other fasteners (depending on the materials of the ceiling).

Suspensions have various designs

Of all this diversity, the variant with two hairpins is most often used (in the photo above - the third on the right and in the photo below). These suspensions are inexpensive, quickly assembled, make it easy to adjust the height of the ceiling when it becomes necessary to expose it in one plane.

How to use the suspension when installing the ceiling Armstrong

But these suspensions have a minimum height of 25 cm. This is a lot even in some offices, and even in houses and apartments, and even more so. The way out is to shorten the hairpins (as in the upper photo on the right) or use improvised materials. The most suitable are steel studs with a ring at the end and a piece of elastic steel wire. The disadvantage of this mount is that it is difficult to adjust the height of the suspension. You have to make them exactly the length that they are needed.

How can I replace the suspensions

Also suitable dowels with hooks at the ends. But here, too, additional hooks made of wire will be needed, since too small a distance to the ceiling will not allow laying the slabs - you need space for maneuver. The minimum distance between the main and the false ceiling is 25 mm and that will be very inconvenient. It is desirable to have at least 50 mm. But this is only if fixtures or fans are not installed in the ceiling.

Lamps and ventilation grilles

Established lamps and ventilation grills are well suited for offices, retail halls, public and medical institutions. They are the same size as the slabs and simply installed in the chosen place. There are no problems with connecting lamps - an extensive ceiling space allows you to bring wires of the desired cross section without problems. They are placed in metal trays fixed to the ceiling or cable channels.

An example of the use of lamps and ventilation grills in the office

In apartments and houses, standard fixtures look, at least, strange, and the power is clearly more than necessary. In this case, recessed spotlights are usually used. It is better to take with LEDs - they almost do not heat up and consume little electricity, and give enough light.

The use of ventilation grids in houses and apartments is rather an exceptional case. The system itself is leaky, many plates with perforation, which provides a sufficient degree of ventilation of the ceiling space. If, after all, additional holes are needed, you can either use the standard grid or build in a smaller one by cutting a suitable hole in the plate.

Ceiling Mount Armstrong

Assembling the Armstrong ceiling is simple: you need a drill, suitable fasteners (dowels or screws, depending on the material of the ceiling), it is nice to have a laser level, but you can get by with a water and bubble one. For cutting profiles, you can use metal scissors, or you can use a grinder with a cutting disc or a hacksaw with a metal blade.

Armstrong suspended ceiling mounting technology steps looks like this:

- We mark on the walls the level at which the suspended ceiling will be located. It is easier to do this with a level, more difficult to do with a bubble level.

- We fix the wall profile along the planned line. There are profiles with different widths of shelves, do not confuse during installation - the shelf should be the same size as the profiles. Fix to the walls with suitable fasteners every 50 cm.

Fixing wall profiles

Better draw a plan, and then proceed to installation

We hang the bearing profiles and fix them on hooks

We assemble the grill from the profiles

Installation of slabs in Armstrong suspended ceiling system

Here's a step-by-step installation guide for Armstrong. Everything is really simple. It is only necessary to preliminarily think over the layout plan of the plates and figure out for yourself where, at what distance from the walls the bearing profiles will pass. Then everything is going as a constructor.

Photos of Armtsrong ceilings in the interior

These are plates from a design series

Mirrored surfaces on the ceiling in the bathroom

Illuminated milk glass behind the ceiling gives soft diffused light

Even the long corridor looks dull

Large monolithic polycarbonate slabs with photo printing

Diagonal execution is more complicated

A combination of gray metal plates and plain white

An option for a cafe, but the same or similar will look good in a modern interior

On sale you can find tiles made of materials:

- Mineral fiber.

- Aluminum

- Of stainless steel.

- PVC

- Wood fiber.

The most affordable are mineral fiber boards. They are lightweight and have a wide range of textures. Most often they are used in office and retail premises. In the home interior, they look inappropriate. For home choose products made of PVC or wood fiber. Metal plates are used to implement custom design solutions, as well as in rooms with high sterility requirements. They can be found on the ceilings in laboratories, operating rooms.

Mineral fiber boards are fragile. This complicates their storage, transportation and installation. Often, even before laying, corners and edges are beaten off from them. Given the specifics of laying the plates on the bed of the frame, many damage to the edges and corners remain invisible, so they do not spoil the overall appearance.